Energenecs installs massive 400HP well controls with a step up transformer from 480V to 2300V!

Paul Young, the Superintendent of Water Operations and the city council from the Village of North Aurora needed water. Fast. In October 2019 they determined they needed two new wells operational by the spring of 2020. Energenecs received the order to proceed in the fall of 2019 and was able to meet their goal.

Has Energenecs worked with North Aurora before?

Many times! North Aurora has our SCADA system, and we also completed the controls for their East Water Treatment Plant and West Water Treatment Plant.

What were the requirements of the new wells?

The village of North Aurora needed water which required two brand new deep wells (800-1000 feet deep). The engineers sized these deep wells to be 400hp at 2300 volts. A typical well could be anywhere from 10-15hp to maybe 100-150hp. 400hp is gigantic! To reduce the wire size they designed the pump and motor for medium voltage 2300 volts, so the motor 800 feet underground operates at 2300 volts.

Was this one of the largest well pump VFDs Energenecs has supplied?

No, we’ve done others, one of them was North Aurora well number seven!

What was the well building process?

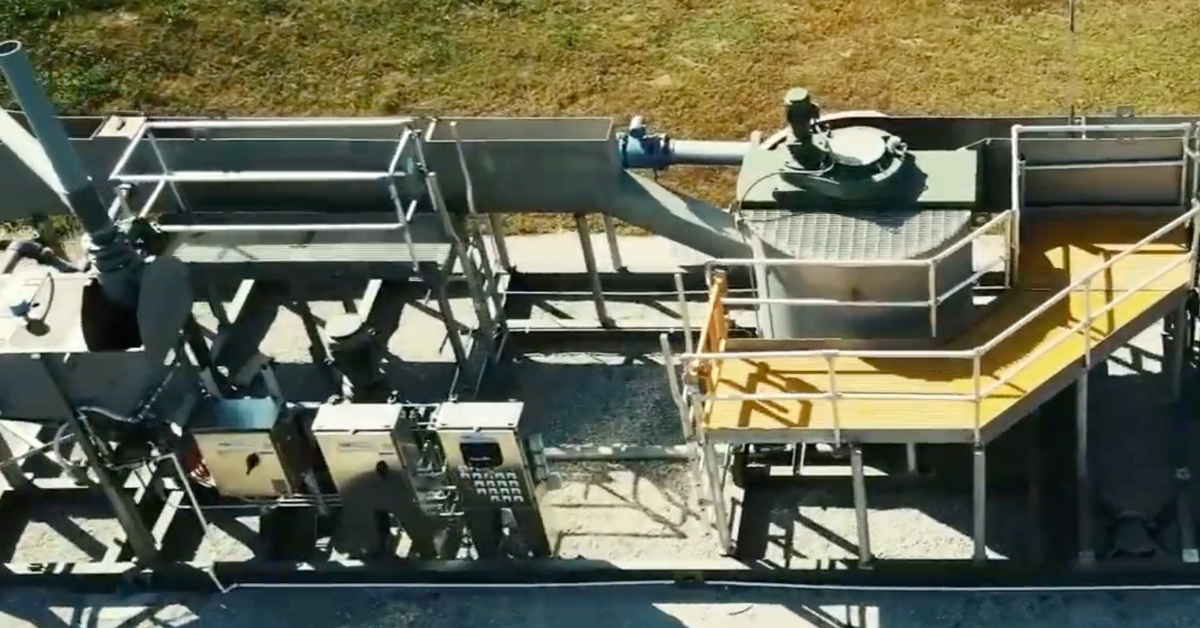

We bought two separate structures from a company called Trachte in Oregon, Wisconsin. They build prefabricated small buildings for the military, airports, hospitals, etc.. The two steel buildings had steel joists with brick exteriors that were 14 feet wide by 22 feet long by 10 feet high.

The buildings were shipped to Energenecs on a flatbed truck one at a time for the installation, assembly, wiring and testing. Inside these buildings we took the incoming 480 volts at 1200 amps and added a motor control center and a 400 hp Allen Bradley 755 VFD (Variable Frequency Drive).

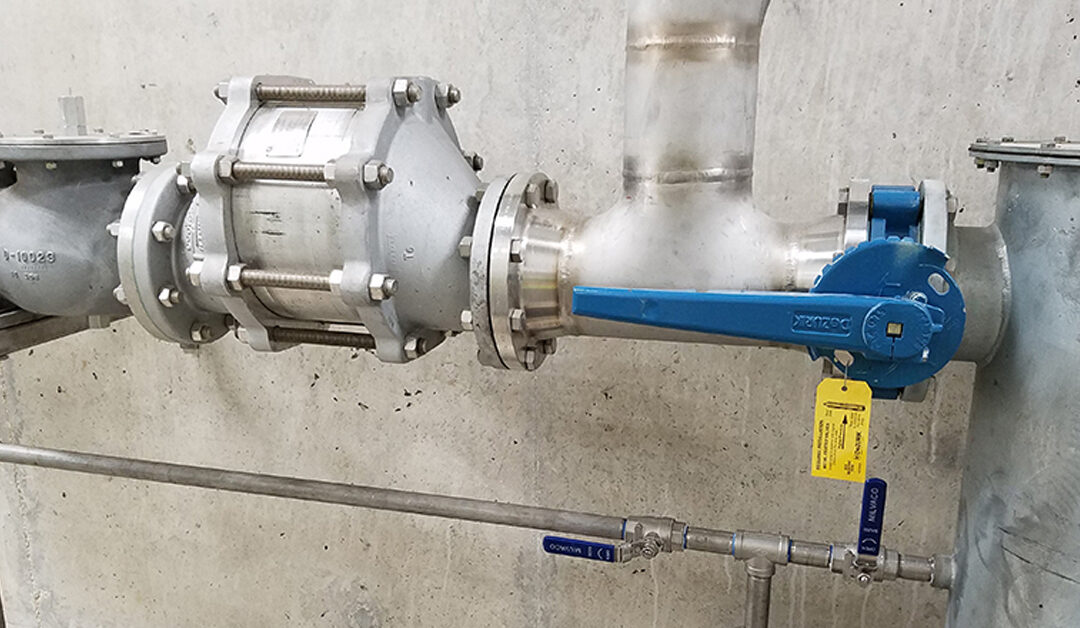

The output of the VFD was wired to a 400hp output filter. This is required due to the distance from the VFD down to the well motor. A unique facet about this installation was we also mounted and wired a step up transformer in the buildings between the load side of the VFD and the pump motor which transformers the voltage to the well pump at 2300 volts. That oil filled transformer was also very large and very heavy (6000 pounds!).

Controlling each well is a wall-mounted Allen Bradley PLC controller, and a 900 MHz radio for communications. We were responsible for all of the programming of the well house controllers, and color touchscreens, as well as the master SCADA software required to provide remote control, monitoring and alarming of wells 8 and 9.

From the time we received each Trachte building at our UL shop, we mounted, wired and tested everything within 8 days. The building stayed on the flatbed truck so all of this heavy conduit and wiring was done outside the shop.

At the North Aurora well sites, contractors poured concrete, connected the piping and brought the main electrical service to these well buildings. The general contractor lifted our 37,000 lb buildings with a crane onto the poured concrete pads.

Also unique with these buildings was the size of some of the conduit. Each building had many 4-inch conduits and very large 500 kcmil wiring. The planning and engineering to make sure that the large conduits and wire design layout in the building and under the building had to be pre-designed and pre-engineered very precisely by Brad Mentink of Energenecs, with the engineer’s approval. This was critical so that our equipment could be mounted on the floor in the building, and not violate the structural integrity of the steel floor joists. In addition, the completed building electrical components had to fit over the top of the site electricians underground conduits.

What were the main challenges of these well house contracts?

Speed! Speed! Speed! I was on the phone with Paul Young and the city council of the Village of North Aurora in October 2019 and they told us they need one of these wells operational by spring of 2020. We said Energenecs can do that, and received the order to proceed in the fall of 2019. The goal was to get the well 9 delivered in early April, and we met that deadline. The goal for well 8 was late April or early May and we were able to deliver that well structure 2 weeks ahead of schedule!

We had to have the motor control center, VFD, filter, transformer, PLC control panel and all of the loose components delivered and on hand in order to assemble these buildings in a very short window of time, therefore coordination was vital to this project. Special thank you to the Energenecs team who participated on North Aurora – Brad Mentink, Dave Simon, Joel Brill, Jacob Hofman and Don Miles all played a significant role… It took an enormous team effort!

0 Comments