The best thing we ever did

adding RoK4 vertical fine screen wastewater to our headworks

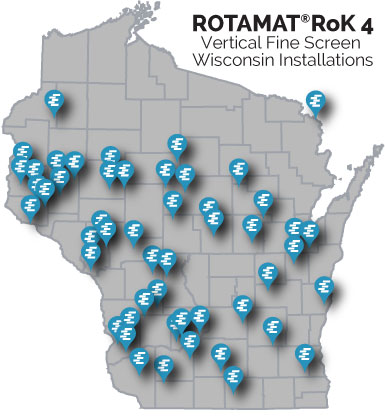

Energenecs provided the first HUBER Pumping Station Screen ROTAMAT RoK4 in 2005, which vertically lifts screenings, dewaters and compacts them at the same time. The RoK4 vertical fine screen wastewater is currently installed in 60 locations throughout Wisconsin.

What is the challenge that the RoK4 addresses?

There is an issue with consumer products labeled “disposable”, such as wipes and other things that create a big headache for collections systems. As a result, plants have problems with pump station pumps and other process equipment getting clogged up.

In the past, operators used manual bar screens, which required them to rake the bars everyday, and they have also used grinders or comminutors to prevent pump clogging. These technologies are subject to high wear, and require frequent maintenance in dangerous environments. The RoK4 is an automated screening system that helps eliminate these issues. For pump stations, the RoK4 helps reduce pump clogging issues by positioning the screen in front of them. They are also used as the primary influent screen at many wastewater plants. Whether it’s a mechanical plant or lagoon system, many use the RoK4 at the head of their process for screening. Upstream screening also protects pumps from clogging and permits use of high-efficiency pumps. In addition, removal of coarse solids protects sewers by preventing deposits and reducing septicity, odor and concrete corrosion.

How does the RoK4 vertical fine screen wastewater work?

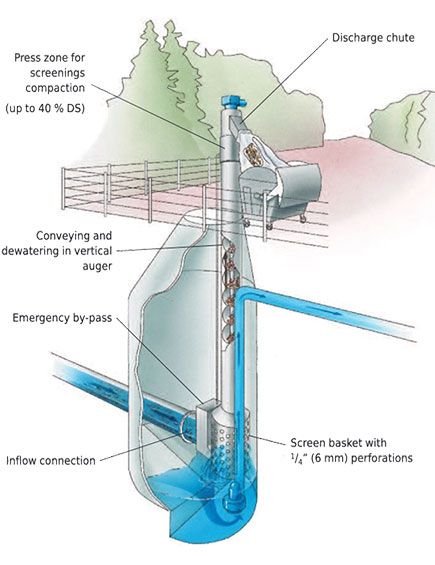

The screen consists of a vertical perforated screen basket and a shafted auger in a vertical tube. The wastewater flows through an inflow connection and a chamber into the screen basket. Within the screen basket the flights of the screw are equipped with wear-resistant brushes for effective cleaning of the screen. As the screenings are gradually elevated by the auger, they are dewatered and washed.

The compacted screenings are discharged into a container or endless bagger which help eliminate odors. The screened wastewater flows off by gravity or is pumped to a higher level. The top of the inflow chamber is open and serves as an emergency bypass so that the machine can be submerged without problems, for example, in case of a power failure.

What are the advantages of the RoK4?

The advantages of the RoK4 is that they are very compact and fit easily into confined spaces, such as wet wells and manholes. It’s all vertical, you don’t need a lot of floor space for it. It does everything in one: it removes the screenings, compresses and washes them and then finally delivers them to a dumpster or other type of container. The screen includes a continuous bagger which makes it very convenient for screenings disposal.

The nice thing about the RoK4 screen is that there are no surprises. It operates as promised, it’s a very reliable system. It’s all stainless steel, they are built in Germany and in North Carolina. They are very corrosion resistant and last a long time. Other than changing the oil in the gearbox and changing out that brush periodically, the intended service is probably twenty plus years.

What are the site requirements?

Normally we recommend to most of our plants to install the RoK4 indoors. It doesn’t have to be in a fancy building, sometimes it’s just a little fiberglass hut. If they have to be installed outside (we have a couple of those) there is a cold weather protection package, which can protect the system well below zero.

What about maintenance for RoK4 vertical fine screen wastewater?

They are really easy to service, there’s not a lot of maintenance on them. There’s an auger brush that periodically gets replaced by Energenecs service personnel who are factory trained to service the screens. The clients can call our service department and have them come out and replace the brush in a few hours. It also has an optional rail system. They can pull the screen out on a rail vertically and they can easily access it from ground level.

How often do the brushes need replacing?

It depends on how often the screen operates, which depends on how dirty their wastewater is. Typically they are replacing the brushes every two to four years.

Village of Oostburg Retrofit: The best thing we ever did

Instead of spending additional dollars on designing and constructing a new headworks facility, the Village of Oostburg and their consulting engineer, Diane Thoune from Crispell-Snyder, Inc., decided to replace their existing, ineffective comminutor with the RoK4 in 2006. The complete project cost was under $300,000 for the retrofit. J.F. Ahern Co., performed the installation. Energenecs worked with Phil Dulmes, the plant superintendent at that time, and Crispell Snyder’s engineering staff to make this retrofit happen. Phil said, “This is the best thing we ever did – adding RoK4 to our headworks. We no longer have to manually clean rags and other debris weekly from our grit chamber. This basket with 1/4″ openings captures everything – including grit.” The final screened product is compacted and bagged for easy disposal. Greg Lemahieu, former Plant Operator and Current Superintendent remarks “We have improved the quality of our solid screenings and reduced the workload on our downstream components. We’re ecstatic with the fact that the periods between rebuilds for these components have increased since putting RoK4 in place. That is significant to our overall operational costs since each rebuild can run several thousand dollars. The RoK4 Vertical Fine Screen is an amazing solution. It works just as well today as when it was brand new. It has been clean as a whistle since day one.”

Village of Baldwin: Liked it so much they bought 2 more!

Gary Newton, Water/Sewer Foreman at the Village of Baldwin remarks “The Rok4 has worked very well for us. The current plant (.392 mgd) is quite old, and it was tough to climb down in the confined space and clean the rakes all the time. So we put the RoK4 in to keep the guys out of there, which also saves us time from manually cleaning.” Beginning summer of 2021, a brand new plant in the Village of Baldwin is being built and will also have two new Rok4s vertical fine screen wastewater installed (one for redundancy).

Arcadia Water & Wastewater Utility: Recommends for high flows

The Rok4 was installed at the Arcadia Water & Wastewater Utility in 2008. Ray Suchla, Superintendent, remarks “The vertical screen has been working well for us. With Arcadia we have higher flows with wet industry in town (a chicken processing plant) and I would advise the screen to anyone that has higher flows. We have had Larry Claude of Energenecs out to replace the wear bar and brushes in the past and have had good luck.”

What size plant is the RoK4 work best for?

Typically, the RoK4 vertical fine screen wastewater is best for plants less than 4 mgd. Higher plant flows can be accommodated with the use of multiple screens. Some of our smaller plants use the RoK4 in wastewater flows as low as 50,000 gpd.

For more information about the RoK4 vertical fine screen wastewater

Contact Emily Vebber at Energenecs for more information.