80% Solids Capture using EscaMax’s Perforated Plate Screen

Many fine screens on the market today typically only capture 35-50% of the solids in wastewater, Energenecs has found that the HUBER Belt Screen EscaMax combines separation efficiency with operational reliability. We asked Steve Berggruen, P.E. from Energenecs about EscaMax’s perforated plate screen technology.

What does the EscaMax technology replace?

The EscaMax can replace conventional multi rake bar screens and step screens if operators want a higher solids capture rate.

What are the main benefits of EscaMax?

If you can capture more screenings earlier in the treatment process, then they don’t end up settling out in downstream treatment processes and/or clogging pipe and pumping systems. Eventually downstream basins get filled with debris which makes the other equipment downstream work harder. It’s good to get the solids out early. It is also a very compact system with minimum space requirements and is easy to retrofit into existing channels.

How does the EscaMax perforated plate screen work?

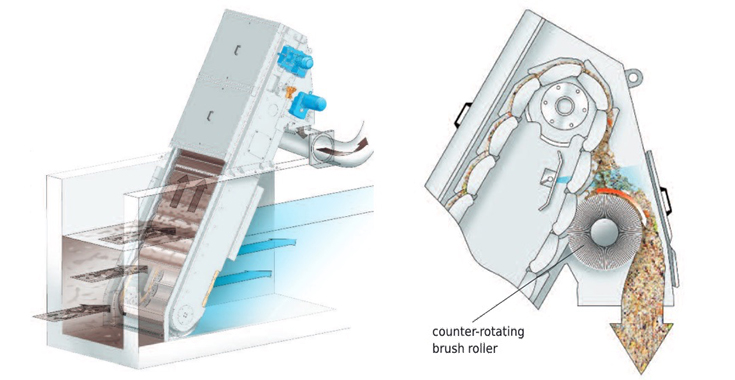

The EscaMax has two drive units on it. One drive to rotate the screen and the other drive with a brush, The perforated plate screening media filters out the solids in the wastewater stream. These “tiny holes” eventually get plugged up with solids. Every time the screen goes through a cycle and a rotation, there is a spinning brush that cleans those holes. Because you are capturing so much more material, you are going to save on wear on pumps and other mechanisms downstream.

The screenings are washed with a HUBER washer press and then transported to a dumpster for disposal.

What size plant is it applicable for?

The EscaMax can cover a wide variety of flows, from 250,000 GPD to over 100 MGD (with multiple screens in parallel). The EscaMax is particularly well suited in situations where excellent separation efficiency is required in deep channels with high water levels.

Where has the EscaMax been installed in Wisconsin?

Two in the Village of Holmen and one in Grafton (2.5 MGD). The Grafton plant was only started about 8 months ago and the screen is running very well. The attraction for Grafton from the engineer was that they wanted to capture 80% of high solids, that’s what this screen does.

The Village of Holmen liked it so much, they bought another one!

In Village of Holmen’s headworks building, they had two channels. One was for the new EscaMax and the other channel was for future expansion, or to use for bypassing. The first EscaMax was installed about two years ago and immediately the comment from the plant was that they were getting lots of screenings collected. More than they ever saw at their old plant. They really liked the operation that produced about three times the amount of screenings. That’s what the EscaMax is known for, it does a very good job of capturing screenings with their perforated plate screen. In fact, HUBER did some studies and found it captures over 84% of the solids in wastewater, which is really good because when compared to other screens, they might only capture 35-50%. The Holmen plant liked it so much, when the contractor was still on site, the Consultant approached Energenecs and wanted to know if they could get a second screen to put in the empty second channel. The second EscaMax was installed and is running as well.

For more information about the EscaMax

Contact Emily Vebber at Energenecs for more information about the EscaMax perforated plate screen, which can capture 80%+ of solids, far greater than the typical 30-50% fine screen capture rate.