Energenecs brought a Village Well Back to Life!

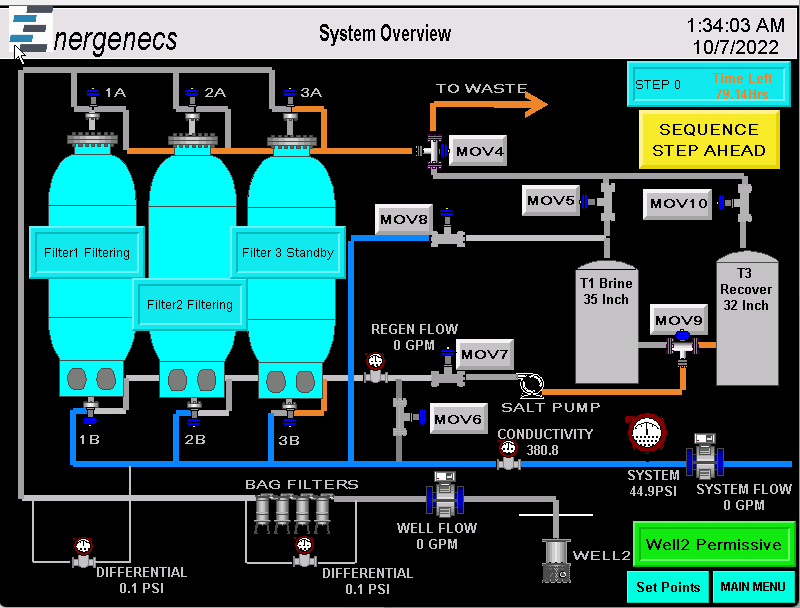

Suring Public Works Department had a deep well and water filter plant which was designed for arsenic removal. There were issues with the filters plugging and not performing as it should. Energenecs was brought in to assist this problematic well and filter system with an updated controls system.

What was the problem they were having?

They were looking to rehab their well #2 in the community. This well was done some years ago, and it was put into operation, though it was never able to perform as designed when they drilled the well. One of the reasons they wanted this well to be part of the system, is that the Village of Suring exists on two sides of a river. They didn’t have any wells on this side of the river, which is where the main part of the town resides. So the Wisconsin DNR really wanted them to have well #2 available. This well had been offline for 5-10 years and Jeff Tienor, the Director of Public Works, took it upon himself to review some other options to get this well running and available again.

Is arsenic a common issue?

It’s not very common that communities have to deal with it, but it’s certainly something that does exist in some water systems, and you definitely don’t want it in your drinking water. Arsenic is actually natural in the ground, it unfortunately is more prevalent in some areas versus others. It becomes more prevalent when the aquifer becomes more depleted, then it starts leaching into the water a little more easily. As long as it stays submerged in the ground, it typically isn’t an issue. Unfortunately, the Village of Suring has it in their water system, so they need to remove it through filters.

Why wasn’t the well operating?

This is a deep well and water filter plant which was designed for arsenic removal. There were issues with the filters plugging, and simply not performing as it should. After all of this time, Energenecs was brought into the project. They wanted us involved because we did the overall SCADA system in Suring and they liked our services being more local in Wisconsin to assist this problematic well and filter system.

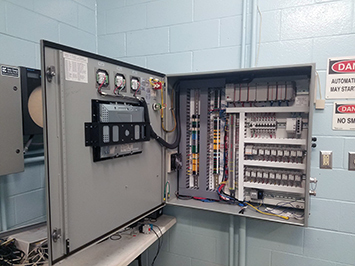

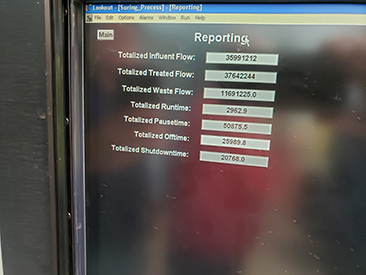

The previous filter control system used a programmable logic controller (PLC) which was configured using proprietary software code. This proprietary and cumbersome code was displayed on an old XP computer at Well #2. Based on the control software we inherited, Dave Simon and Craig Sampo, from Energenecs, essentially “reverse engineered” the control logic for this arsenic removal plant and did a full upgrade. Dave added a useful local color operator interface to provide more meaningful site data to the operations staff.

What was the process?

Jeff Tienor, the Public Works Director, asked Dr. Andrew Jacque, P.E., Chief Scientist and Founder of Water Quality Investigations for some expertise. Dr. Jacque then studied the characteristics of the well, to try a different process. They took what he recommended, and Energenecs was able to change how the filter plant operated to return the filter process back to life.

The arsenic removal media became fouled with a sulfate reducing biofilm, which caused poor treatment performance. Chemical cleaning of the well, abandonment of a dead-zone in the well (source of iron and biofilm), routine cleaning of the media, and switching to peroxide feed for oxidation of arsenic and iron, and for control of biofilm on the media solved their treatment issues.

The Village had a well service company pull, changed some screening and the depth of the well. Then they brought in Energenecs to upgrade the PLC and to get the controls to function properly with the changes they made. Dave Simon and Craig Sampo were tasked with handling this project. Dave did the programming and both of them worked together to bring all of the equipment that hadn’t been used in many years back into service.

How long did it take to implement?

It took a few months to get things switched over, rewired, install new programmable controls, and then perform a field startup and test phase to make sure that the process worked as the new design called for. It turned out fairly well actually. We were all very pleased with the outcome. It was definitely a challenge! Dave and Craig both enjoyed working the project.

Craig Sampo

Craig has been the lead service technician for Energenecs since 2006 and is responsible for managing the field service team. He typically works on instrumentation (DO meters, phosphorus and ammonia analyzers, various flow meters, including ultrasonic and radar equipment), chemical feed and process equipment (fine screens and aeration) problem solving. Controls-based problems are another area he works on including SCADA and relay controls, lift station panels, wells, and other related water and wastewater treatment activities.

0 Comments