Meet Tom Robarge, SCADA technician at Energenecs

A SCADA (Supervisory Control and Data Acquisition) technician is responsible for operations and maintenance of the communication channels connecting computers with remotely controlled water and wastewater equipment, as well as the equipment in the network. We asked Tom a few questions about his history and role at Energenecs.

What is your work history and experience?

I went into the Navy’s nuclear power program, where you can be a reactor operator, electrician or mechanical operation. My first choice was an electrician, and I started training for it after boot camp. After graduating from the “A” school, where I learned my electrical background, I was sent to an intensive nuclear power school, where you studied onsite because there was a lot of classified material. Once I passed that school, I was sent to a prototype in upstate New York, qualifying to operate a reactor in the engine room. Once I graduated from the prototype, after two years of schooling, I was considered a nuclear qualified electrician.

From there I was sent to Connecticut aboard the USS Pennsylvania submarine in new construction. This was one of the larger submarines, about 3 football fields long and the engine room had three levels. We finished building the submarine and brought the reactor online. I went through all the sea trials, and did the first patrol. We transferred down to Kings Bay, Georgia and spent three to four years doing patrols, going out to sea a couple months at a time. The longest I was under was eighty days.

When we took off from the west coast we would dive within several hours of leaving port, but on the east coast we had to transit for about a day before submerging. We could go up on the bridge and see the stars and sometimes get lucky and see the dolphins riding the bow wave. Typically we were submerged around 400 feet, and we had to maintain communications, either by antenna or radio buoy setup near the top of the water. As we would change the depth, it would let wire out or pull wire back in. On a week long trip we would do drills a few times a week preparing for inspections. We had to pass an Operational Reactor Safeguard Examination once per year. That’s where inspectors would come on board and run drills on us, like scram the reactor, simulate steam leaks or fires, any kind of failures of different equipment and we would have to respond and react. When you have reactors scrambling and have these inspectors in there, you can barely move, but you have to keep the electric plant up. When we would go out to sea we would shift our clocks so daytime was actually at night. We did this when we ran drills, so if we shut down the reactor and had to run diesel the smoke wouldn’t be picked up on satellite.

Sounds like you are able to work great under pressure!

When I look back on it, I learned a lot, it was a great experience. After the patrols, I went back up to prototype in New York, and became an instructor. I did classroom training for about four years. We also brought the Sea Wolf (a class of nuclear-powered fast attack submarines) core out of initial criticality. During this time I also went to night school and got my degree in human resources.

They transferred me out to Washington state and I decommissioned a submarine. I was the electrical petty officer there and we took the reactor out of the submarine and sent it out to be buried in Idaho. Then they sent me out to the USS Alabama, which was featured in the movie “Crimson Tide”, and I went on two patrols. This completed my eleven years in the Navy.

What did you do after the Navy?

I worked at Firestone in Decatur Illinois as a maintenance electrician. That is where I got into learning about PLC’s (programmable logic controller) and SCADA type applications. I learned very quickly that when a machine stopped working I could look in the program and find out why and where the machine stopped. I studied the PLC’s and found them interesting. At the time I took a position as a controls supervisor and worked with the controls engineer. That engineer left Firestone and went to work for a company in Champaign, Illinois doing water and wastewater controls. He called me after a couple of months and asked if I would work with him, so that’s how I got into water and wastewater. That was in 2001, I have been doing water and wastewater controls for eighteen years now. That company also allowed me to live in Wisconsin near my family, and work on Illinois projects. I met Brian Akason from Energenecs during this time and brought him in on a project. We teamed up and hit it off pretty well. Shortly after that I met Jared, president of Energenecs, who offered me a position, which I was happy to accept. I have been at Energenecs for almost nine years now.

Is there is a typical project you work on?

No [laughs], that’s what I enjoy about this job. When people ask what I do, I tell them I just figure things out. We basically integrate things we make systems work. We take engineers designs and we make it into a working application.

Most of the projects have some commonality, so we try to reuse what we can to be more efficient, but every project is different. Sometimes a community wants to know every single alarm coming in from a lift station, others just want to know about a high level in the wetwell or a power fail.

Recently I worked in Spooner, WI. which has a few wells and elevated towers and I spent a week programming, testing and getting equipment ready remotely, then another week at their location starting everything up. As a contrast, the wastewater plant in Eau Claire was a major two to three year control upgrade project, I spent almost everyday there.

What do you enjoy about your job?

Every project there is something different, some new challenge on it and that is what I like about it. I’ve established a lot of good friendships throughout the state. I like working in different communities and learning about all the things going on in Wisconsin. Last fall I did a project in Clintonville and learned they make fire trucks in town!

What was a challenging project?

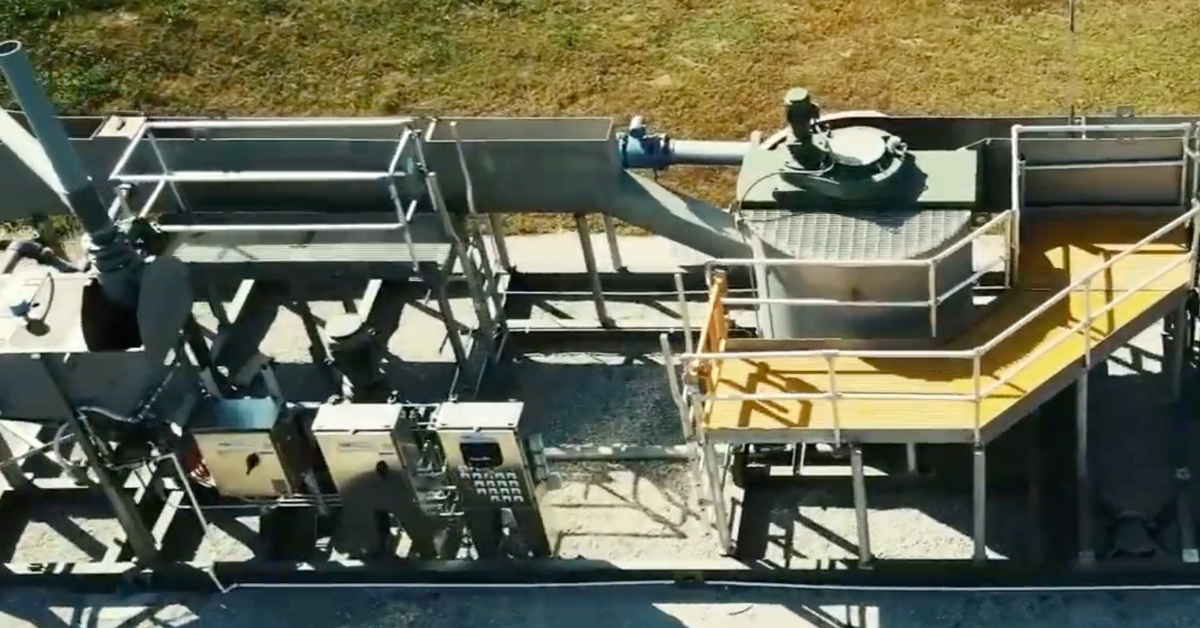

Eau Claire was a 40 million dollar upgrade throughout the plant and had five different huge redundant PLC cabinets. They changed basically over from one process to another. It’s challenging keeping processes running while you are upgrading. By comparison, I have worked on a larger 14mgd brand new wastewater plant which was much easier! Everything at Eau Claire is now much more automated compared with what they had. They doubled the size of their belt filter presses and gravity belt thickeners and used a lot more gas for their boilers and gas engines that help with their power. They also went from a RBC (rotating biological contactor) process to an activated sludge where they had to seed it with bugs from Chippewa Falls. I also worked with other companies that were bringing in different pieces of equipment that had PLC’s to integrate together and make them all work. Currently I am working on the Eau Claire water SCADA and control system as they are now starting a 10 million dollar water treatment facility sedimentation addition project.

What else have you been working on recently?

Upgrades to Windows 10 has been driving a lot of work lately. Windows 7 is set to stop support January 14th 2020, which could cause security and other issues in the future. We are getting many calls regarding this, I’ve been upgrading computers all summer!

When you have time, what do you like to do for fun?

In the summer, my wife and I enjoy landscaping, gardening and sitting on our deck enjoying the flowers and birds. We also like to explore different golf courses around the state. We are huge Packer and Badger fans and we also participate in curling during the winter!

*Curling is a sport where players slide stones on a sheet of ice towards four marked circles called the house. Points are scored for the stones resting closest to the center of the house.

0 Comments