WWTP Seeks to Optimize Polymer System

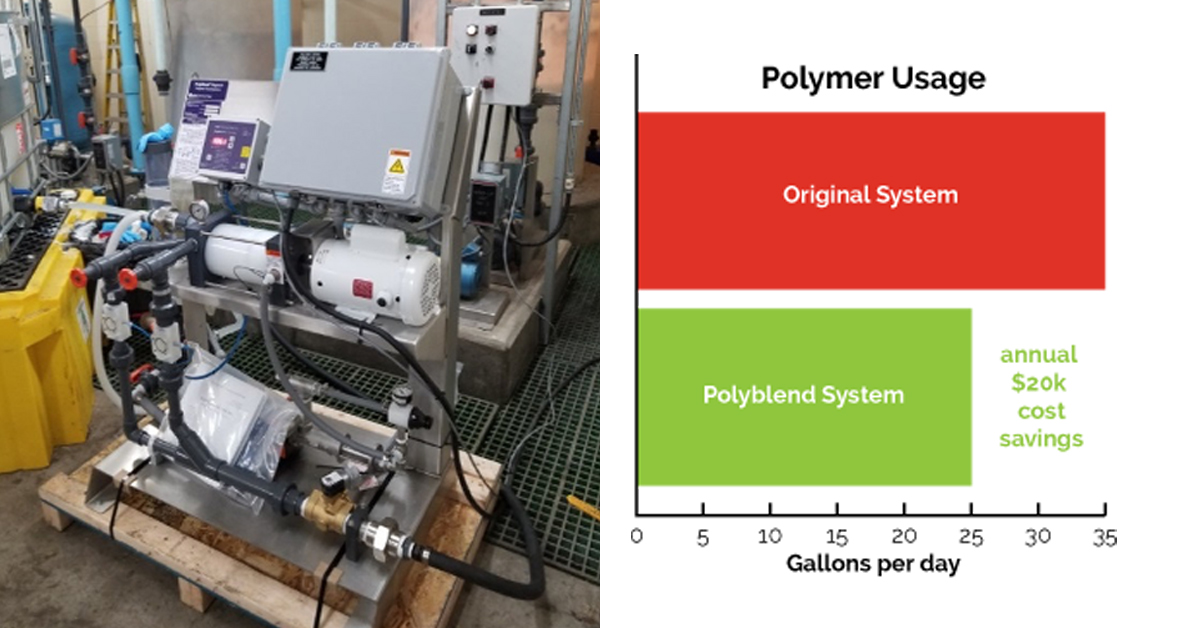

Fort Atkinson WWTP had an existing polymer system, but the operators sensed it required too much polymer and were seeking out how to optimize their polymer system and lower costs. In August of 2019, UGSI Chemical Feed, Inc. and their local Wisconsin representative, Energenecs provided a free demonstration of the Polyblend-Magnum skid mounted polymer system.

About City of Fort Atkinson Utilities WWTP

Fort Atkinson is a city located in southeastern Wisconsin with a population of about 13,000 people. The original wastewater treatment plant (WWTP) was built in 1972. At that time, it was a conventional activated sludge design and since been upgraded a several times, in the 1980’s and 1990’s with additional processes including aerobic digestion, sludge storage and centrifuge dewatering

WWTP Seeks to Optimize Polymer System and Lower Costs

As with many WWTPs, a large portion of the treatment plant’s operating budget is spent on polymer, primarily to dewater aerobically digested sludge. At Fort Atkinson, the sludge is typically has a 2% solids concentration and is dewatered via a centrifuge. The plant had an existing polymer system consisted of a polymer tote, transfer pump, static mixer, aging tank and progressive cavity metering pump. The system was effective, but the operators sensed it required too much polymer and started to investigate efficiency opportunities. In August of 2019, Paul Christensen, Utility Manager, Erin Sweeney, Maintenance Supervisor, and Ryan Wagner, Plant Operator were looking for a way to optimize their polymer system and lower costs. UGSI Chemical Feed, Inc. of Vineland, NJ, working with their local Wisconsin representative, Energenecs offered a free demonstration of the Polyblend®-Magnum skid mounted polymer system.

Optimized Energy Sequence Uses Least Amount of Polymer

Polyblend® emulsion polymer activation systems are designed to use an optimized energy sequence in the mixing chamber that has been proven in countless installations and published works to use the least amount of polymer to achieve the best process results. By immediately subjecting the polymer to a high level of energy and then tapering the amount of energy in a second stage in the mix chamber, the Polyblend® system is able to activate polymer without subsequently “chopping it up” once the polymer starts to increase in viscosity.

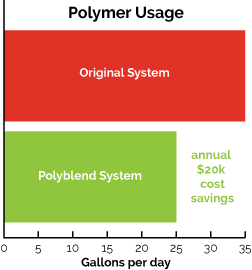

Polyblend System was Able to Decrease Polymer Usage by 25-30%

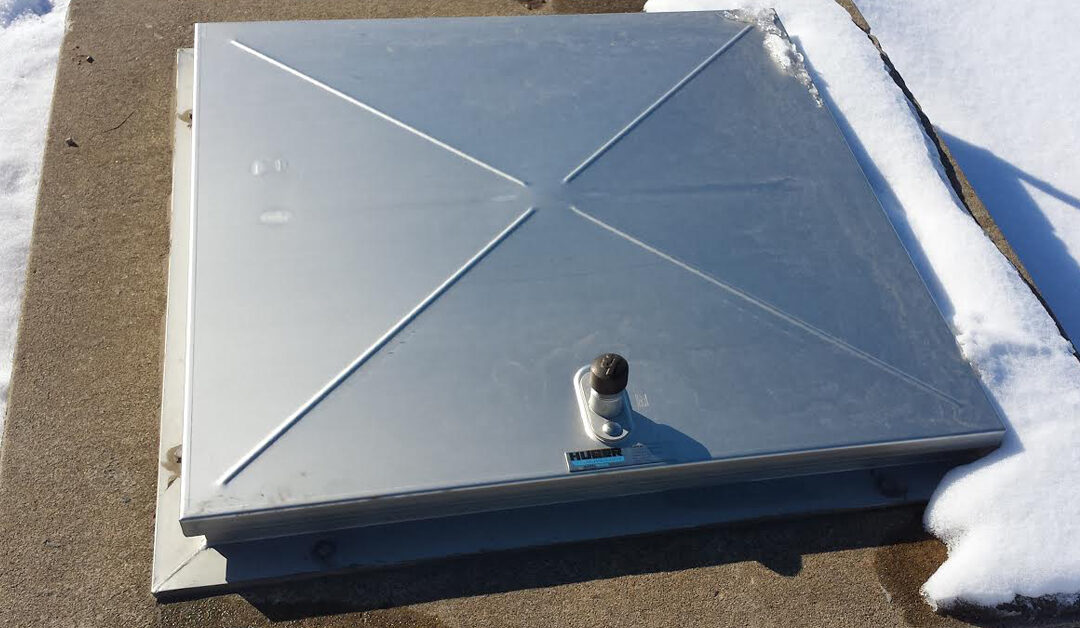

The City agreed to the free-demonstration and began using the Polyblend M-Series in November 2019. The Polyblend® system was able to decrease polymer usage by 25-30% compared to the original polymer activation system and enabled the dewatering equipment to operate more efficiently. Previously, the plant averaged about 35 gallons of emulsion polymer usage per day with the old system. The Polyblend® Magnum system averaged about 25 gallons per day – approximately 30% in polymer savings. The City projects an annual savings of $20,000 which is above the goal they had hoped to achieve. An added benefit was that staff found that the system to be much more space efficient versus the older mix-tank system.

It was a no brainer. We are so happy we changed our polymer system to the Polyblend Magnum system. It has really done the job for us and has saved the City so much in operating costs, specifically polymer.

Based on overall performance, the City decided to purchase the Polyblend® system in December 2019. Erin, Ryan and Paul recently said, “It was a no brainer. We are so happy we changed our polymer system to the Polyblend® Magnum system. It has really done the job for us and has saved the City so much in operating costs, specifically polymer”.

0 Comments