Free Wastewater Aeration Energy Audit

Aeration energy audit of your wastewater treatment plant

The purpose of the aeration energy audit would be to determine the aeration energy consumption and the annual cost of that consumption at your wastewater treatment facility. Energenecs can provide energy saving solutions and to potentially assist with help in getting grant funding to implement those solutions.

Aeration consumes 50-60% of the total energy used

The number one energy consumer in a wastewater treatment plant is the aeration system. Usually 50-60% of the total energy consumed is just getting bubbles into water.

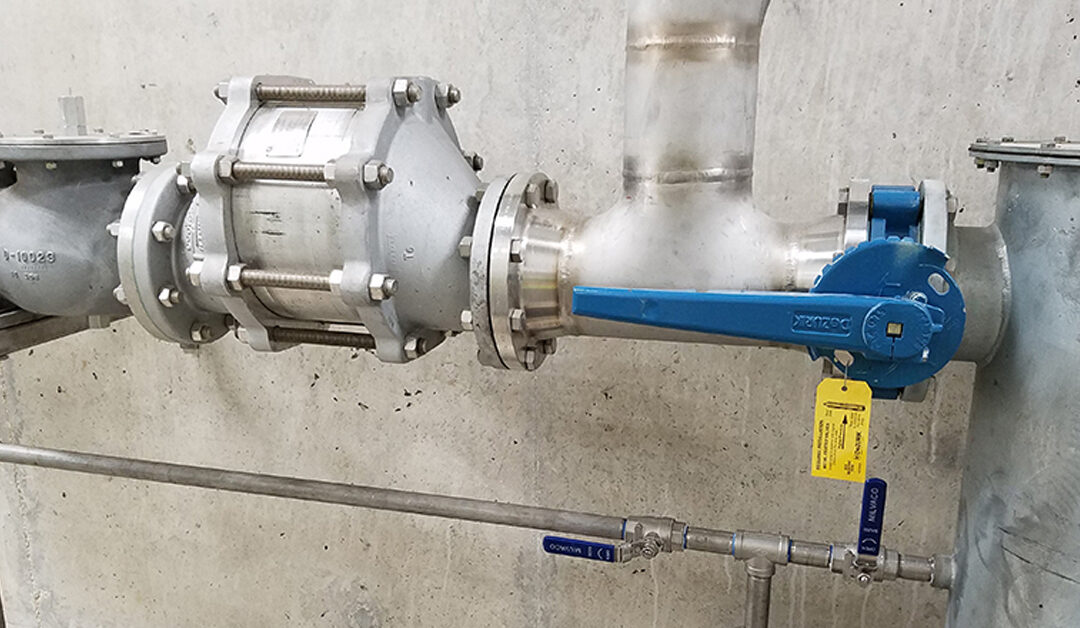

There are three pieces Energenecs’ looks for in an aeration energy audit: blowers, diffusers and sensors/controls. We find out what kind of blowers are used and how old they are. We also look at the aeration system, which is the diffusers on the bottom of the aeration basin. We find out what kind of diffusers they have, are they clean and how old they are. We find out if they have a dissolved oxygen sensor in the basin, or are they just flying blind. Some plants have no monitoring at all, so they have no idea how much oxygen is actually in the water.

Aeration is part of the biological treatment of wastewater.

Wastewater is pulled into the basin that is not fully treated yet. At that point in the process it looks clear, though it contains a lot of dissolved solids. The way we get dissolved solids out of the wastewater is by using bacteria. Bacteria, called activated sludge, is added to the basin then air is turned on (aeration). Those are the three ingredients: wastewater. bacteria and air. Without air, the bacteria cannot consume the dissolved food.

3 main types of aeration: surface, coarse and fine bubble

Three main categories of aeration are surface aeration, where so have something floating on the surface that’s mechanical, like splashing water, usually seen in lagoons. There is also submerged aeration where you have diffusers on the bottom of the basin. Submerged aeration has two types of bubbles: coarse and fine. Coarse bubbles is an older technology that makes large bubbles about the size of golf balls, which is really inefficient because it does not transfer oxygen very well. Fine bubble is a modern technology that produces super tiny bubbles which are the most efficient.

Older aeration systems can have other urgent issues

Older, small plants might they have other problems, where their system is so old, it’s actually failing. Blowers are not working, diffusers are clogged. So they have more urgent issues, besides energy consumption, like not meeting their permit limits.

If you are concerned you have ageing equipment if you don’t stay on top of this stuff it can fail, then you’re in a heap of trouble. For example a Wisconsin wastewater treatment plant’s clarifier recently failed. The mechanism to get the sludge out of the clarifier failed because they had not inspected or maintained it in twenty years. The clarifier started filling up with sludge and then the sludge started overflowing into the next downstream process. If not maintained, you can have this cascading problem where it’s going to start destroying the trickling filter downstream and eventually you’re not going to be able to meet your permit. The same situation could have catastrophic failure and fines from DNR. It’s important to stay on top of it.

Aeration system upgrades provide real savings plus O&M improvements

- New blower technologies can save 25% to 30%

- New aeration technology and higher density design can save 25% to 50%

- DO and controls can save 25%

Aeration Case Study – Antigo, Wisconsin:

Situation

- Ceramic disc, 20 years old

- Multi-tank trains with manual valves

- Single channel DO

- Cheese plant influent

- 125 hp PD blower with VFD

Solution

- New teflon co-extruded fine bubble panel diffusers

- Tapered aeration

- Dual channel/ 2 train optical DO

- 50 hp tri-lobe with VFD

Benefits

- Energy savings of $29,000/yr

- Energy incentive approx $28,000

Aeration Case Study – Menominee, Michigan:

Situation

- Ceramic disc, 1988

- Multi-tank trains with manual valves

- Single channel DO

- Cheese plant influent

- 125 hp PD blower with VFD

Solution

- Energy Performance Contract: No capital, Guaranteed Savings, Limited risk

- New teflon co-extruded fine bubble panel diffuser panels

- Advanced DO control with optical sensors

- New high efficiency PD blowers

Benefits

- 56% energy reduction

- Energy savings of $29,000/yr

- ~5 year payback: Immediate savings with no capital spent for Menominee, due to performance contract

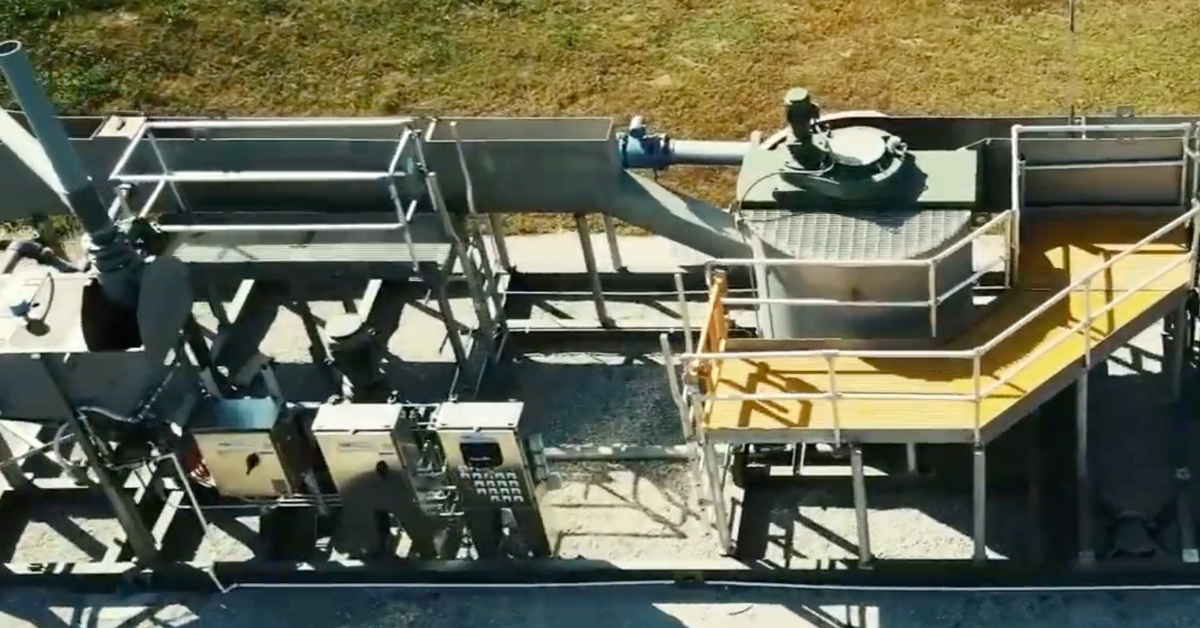

Aeration Case Study – Grande Cheese

Situation

- Surface Aeration

- Needed to replace oxidation ditch surface aerators

- Needed to separate aeration and mixing systems

Solution

- Separate Mixing and Aeration Systems each designed for maximum efficiency for it’s purpose

- Mixing: Submersible large blade, slow speed mixers with VFDs (2 in each ring)

- Blowers: High efficiency Turbo (3)

- Instruments: Optical DO sensors

- Control: DO control

- Retrievable diffuser grids and mixers

Benefits

- 36% energy reduction

- Stable process

- Reduce seasonal variation

- Better DO control in each ring

- Less filaments, better settling

- No overspray

- No oil on ground

Aeration Case Study – Freeport, Illinois

Situation

- Unusual denitrification system with aeration

- Multiple older 50hp PD blowers, one each for seven filters

- No air control

Solution

- Energy Performance Contract: No capital, Guaranteed Savings, Limited risk

- New teflon co-extruded fine bubble panel diffuser panels

- Advanced DO control with optical sensors

- New high efficiency PD blowers

- Installed 2 twin screw blowers, one as standby, 200hp

- Added DO control, blower VFDs

Benefits

- 200hp savings = $123,000/year @ $0.1/kwhr

- Improved blower efficiency over 25%

- Savings estimated at 50%

- Received energy incentives over $400,000

How to get a free wastewater aeration energy audit

Contact Trevor Ghylin at Energenecs to schedule your free evaluation at 262-377-6360 or click on the orange button below. The audit will take an hour or two onsite. Energenecs will provide a written report on findings.

0 Comments