New Wastewater Facility for Biggest Little Town in WI

The Village of Baldwin is located in St. Croix County, located in western Wisconsin, known as the “Biggest Little Town in Wisconsin”, with a population of around 4,000. Their old wastewater treatment plant was no longer able to support essential residential, commercial facilities, economic development, and meet current DNR discharge limits. Furthermore, a significant portion of the existing equipment and supporting facilities were approaching the end of its functional lifespan. A new wastewater plant was designed to address these issues and bring the community in line with discharge permit standards. We spoke to Brian Akason, technical sales at Energenecs about the project that was completed this summer.

The Village of Baldwin is located in St. Croix County, located in western Wisconsin, known as the “Biggest Little Town in Wisconsin”, with a population of around 4,000. Their old wastewater treatment plant was no longer able to support essential residential, commercial facilities, economic development, and meet current DNR discharge limits. Furthermore, a significant portion of the existing equipment and supporting facilities were approaching the end of its functional lifespan. A new wastewater plant was designed to address these issues and bring the community in line with discharge permit standards. We spoke to Brian Akason, technical sales at Energenecs about the project that was completed this summer.

What did Energenecs provide for this new plant?

The project was bid in early 2021. The design engineers were SEH (Chippewa Falls, WI. office) and Richard Boya of (Electrical & Systems Integration LLC) as the electrical sub-consultant under SEH. Jurowski Construction performed the general contractor requirements, with B&B Electric of Eau Claire tackling the electrical contractor role.

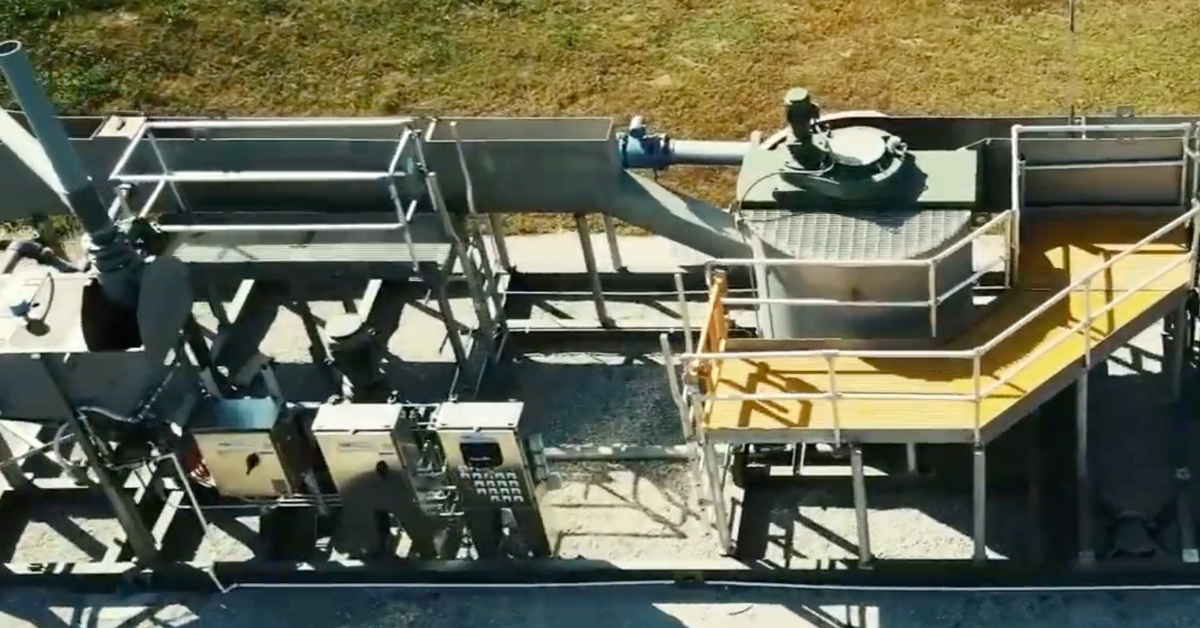

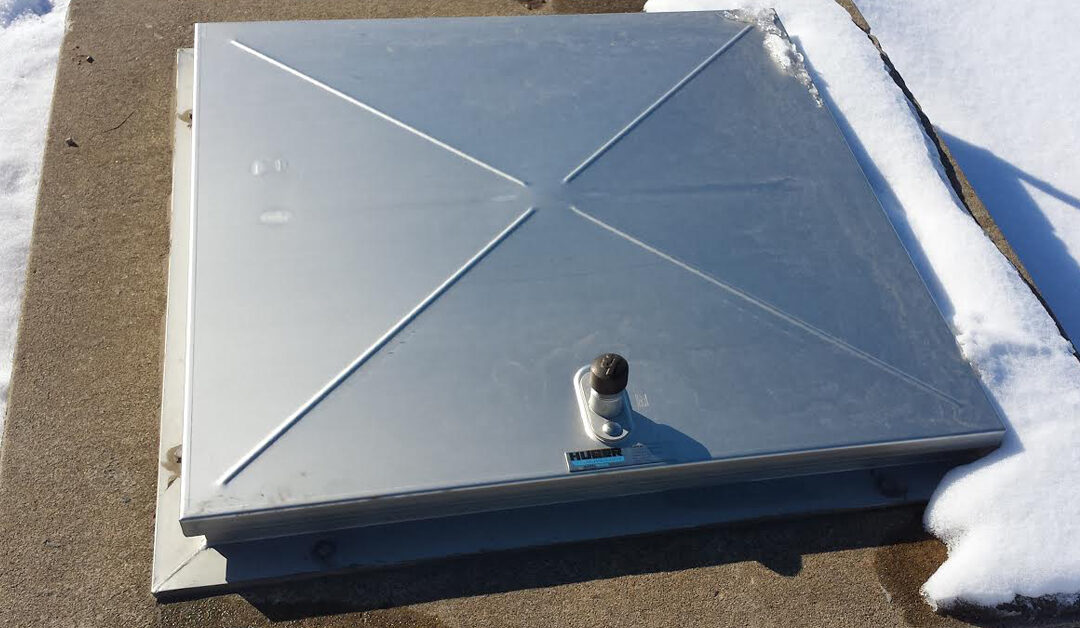

We won the overall SCADA System Integration control system and Motor Control System construction which approached $800,000, so it was a significant electrical and control project. This is a brand new wastewater treatment plant facility “from the dirt” that was located away from the existing Wastewater Treatment Plant facilities, which was completely removed, as it simply was too old and couldn’t meet the newer discharge limits. Often design engineers will save a screen or an existing pump station in the old plant and then pump to the new plant, but in this case, everything is new. Our involvement was controls and new motor control systems that supply all the power to the various buildings and processes. My associate Steve Berggruen, process technical sales engineer at Energenecs, also assisted with two very large Huber vertical fine screens designed for the project.

Gary Newton has been the manager of the Baldwin facility for many years. Gary is also President of the West Central Biosolids Facility in Ellsworth available to nearby communities that do not process their own sludge. The facility is operated by the 11 founding member communities. It’s unique that all these community plants started working together about 20 years ago to create the Biosolids Facility. Gary Newton has been a part of that success from day one.

Gary Newton has been the manager of the Baldwin facility for many years. Gary is also President of the West Central Biosolids Facility in Ellsworth available to nearby communities that do not process their own sludge. The facility is operated by the 11 founding member communities. It’s unique that all these community plants started working together about 20 years ago to create the Biosolids Facility. Gary Newton has been a part of that success from day one.Early on in the project, I stated to Gary Newton that our Brad Mentink will be your control system project manager, with Tom Robarge, located in Rice Lake, working hard on the bulk of your control system programming. Best of the best. The Baldwin facility was a two plus year project because it involves a lot of process basins, equipment, piping and electrical work. When the engineers from SEH did a final walkthrough with Richard Boya, Gary and Adam Newton both commented, “By the way, Tom Robarge and Brad Mentink walk on water.” So that’s how it ended!

“By the way,

Tom Robarge and Brad Mentink

walk on water.”

Now they see what Richard Boya kept telling them all along, “Baldwin is a very large project, you need a system integrator with the stature of Energenecs to provide the required process integration, MCC construction, and the understanding to integrate a control project of this size.” They understand that now due to the complexity of such a project. As educated plant operators, Adam and Gary were a pleasure to work with. They had operated their previous Huber fine screen at the old plant for over 15 years, so including new Huber screens at the new plant was an easy decision. They knew the screens well and even provided Huber with ideas for future screen enhancements.

What was Energenecs scope of work for controls?

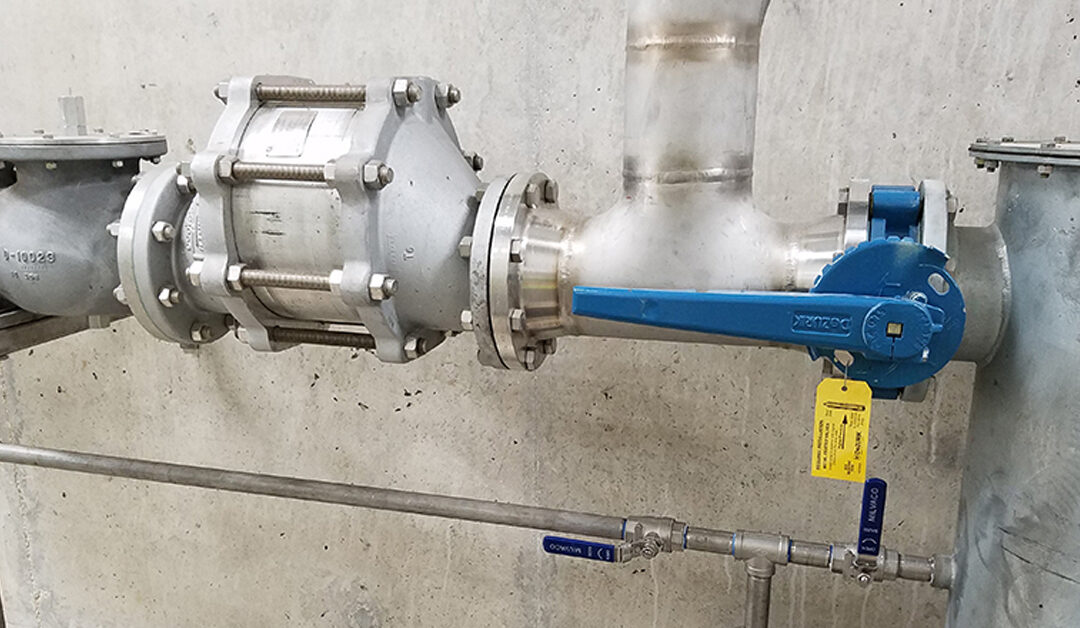

Our scope of work for controls was quite large and involved: One large 1,600 Amp and one 800 Amp motor control centers, each with VFDs, four (4) PLC control panels, and two computer systems running SCADA software (Wonderware graphical software and XL Reporter software). Quite a bit of instrumentation also; meaning flow meters level transducers, pressure transmitters, but also of great significance on a job like this is we had to coordinate and connect to the aeration process supplier’s controls, as well as the effluent filter process supplier’s controls. We had to coordinate the entire facility, all of the connected Ethernet IP addresses, with our overall control software and blend it into one unified SCADA system.

What else was unusual about this project?

It’s large, number one, it’s large. There’s a lot of engineering, wiring coordination and programming coordination for a job of this scope. Not only is the plant brand new, with all new motor control centers, VFDs, instrumentation, PLCs, SCADA software and everything else, but in addition, we connected to Baldwin’s existing water distribution system and all of their lift stations for one overall cohesive SCADA system.

How long did the project take?

The project was finalized this summer and took two and a half years to complete. It’s brand new, all inclusive, and quite impressive!

How often do you work on plants that are 100% new?

Not that often! Chetek Wisconsin is another community in western Wisconsin, where we have another million-dollar control system underway, which is another plant “from the dirt”. But it’s rare. Typically a plant is upgraded on the premises of the existing facility. The final startup and testing phase is always interesting. It gets very critical as the plant comes online with different processes of the plant sequenced, tested, and signed off as complete. This final startup & testing sequence is where our project managers, programmers, and field technicians’ experience and skills come into play.

0 Comments