Energenecs Sold 2nd Energy Efficient HUBER Belt Dryer in Wisconsin to Reduce Sludge Volume

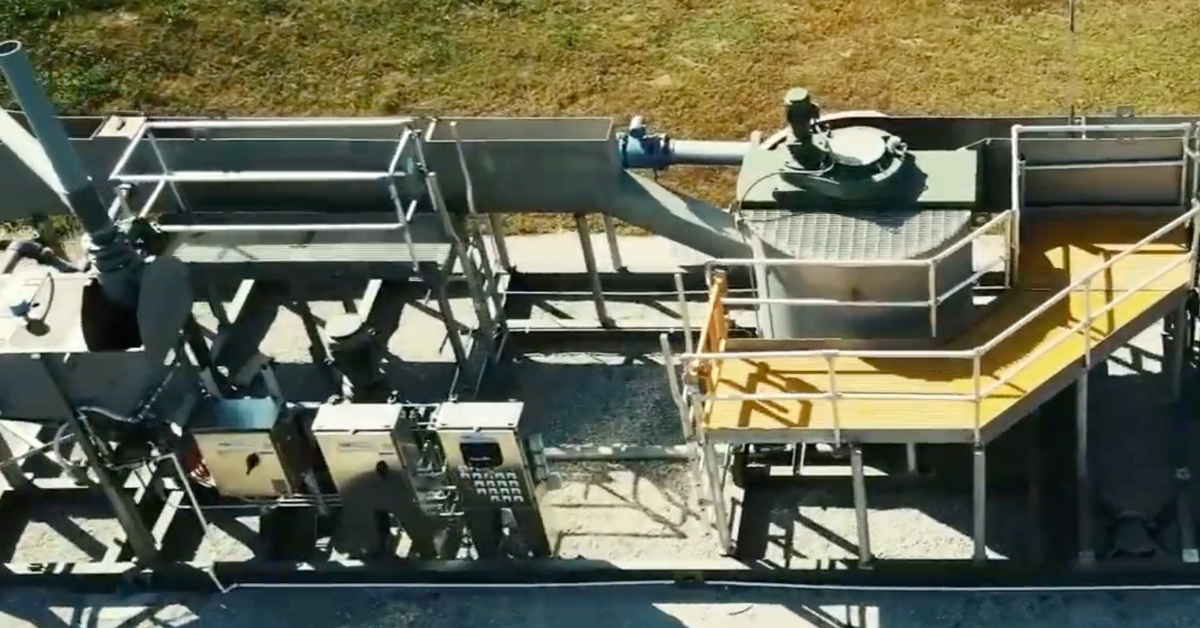

HUBER has many belt dryer installations in Europe and Asia, and they are gaining traction in the United States. In 2014, Energenecs sold the first HUBER belt dryer in Wisconsin at the Sheboygan Regional Wastewater Treatment Facility in Wisconsin. The second HUBER dryer is scheduled to be installed at the Isle La Plume wastewater treatment plant in 2023. The Isle La Plume WWTP in La Crosse, Wisconsin serves as a regional facility and has a design flow capacity of 20 million gallons per day. We spoke to Steve Berggruen, P.E., in technical sales from Energenecs about this upcoming installation.

What are the advantages of HUBER’s belt dryer?

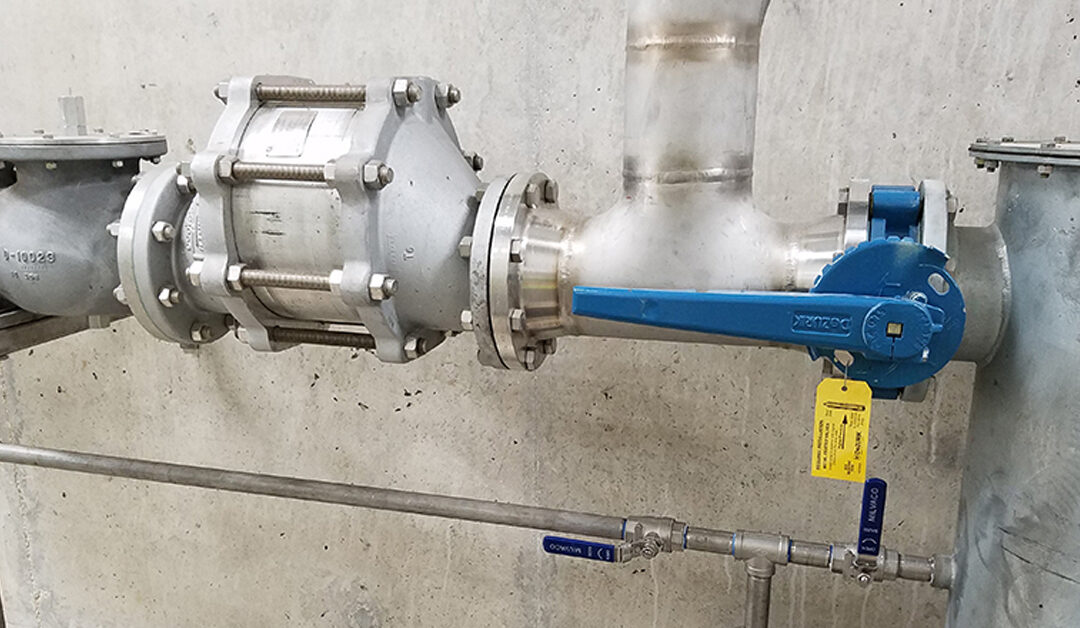

One of the advantages of the HUBER belt dryer is that it is a low temperature dryer. There are other types of dryers that use high temperature to heat oil, like with a screw that is hollow inside. Inside the screw contains the oil and the outside is the sludge. The screw turns and augers it from one end of the dryer to the other. But that requires oil that is heated to 500 degrees F. The Huber dryer requires heating only to 190-285 degrees. It’s very energy efficient.

The dryer runs off of hot water through pipes that heat the air to dry the sludge, like a radiator on a car. The dryer can use waste heat sources such as CHP cooling loops, gas off the digesters as its fuel and it can burn natural gas. It’s very flexible as far as what type of heat/fuel it can use to heat its dryer. La Crosse is going to use natural gas and a combination of waste gas off the digesters.

What was the goal of La Crosse WWTP upgrade?

To reduce the volume of sludge, creating alternative markets for biosolids as class A fertilizer, markets include (Agriculture use, Landscapers, or marketing to local fertilizer companies), this process maximizes the window of reuse of biosolids instead of small windows spring and fall, with current liquid land application. The Huber belt drier also provides the flexibility to use biosolids as energy to create heat and electricity. There is also an option under consideration for incinerating the dried sludge into pure ash.

How are they currently handling sludge?

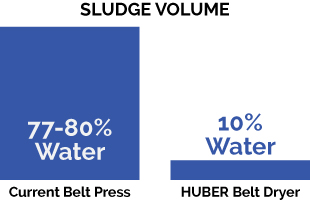

La Crosse has a belt press and they are hauling away sludge cake (13 MG annually) consisting of 77-80% water and 20-23% solids. They are hauling away a lot of water! The new dryer will get to about 90% solids, so you are reducing your water content about six times and therefore hauling much less. The end result is very dry. It’s particles instead of sludge cake, which has the consistency of wet clay.

Where is the sludge hauled to?

They land-apply the sludge mostly 6% liquid very little cake to farmer fields, within Wisconsin, in general. It is becoming more difficult to find fields to spread the sludge on because it’s more competitive. If you have less solids to spread, you won’t run into as much competition because with the dried solids, you don’t need as much land. The farmers are regulated as well because the sludge contains nutrients, like phosphorus, so you don’t want to overdose the farm fields. They can’t take sludge all the time, they have to be careful about overdoing the sludge on their fields, which is not necessarily good for the crops and can create runoff into the streams.

Why did La Crosse select the HUBER dryer?

Donohue is the engineer for La Crosse and they went through a pre-selection process with various dryer suppliers. HUBER and Energenecs were one of those, we were evaluated on cost of equipment, operating cost, energy usage, experience and ease of operation. All of that information was put into a big spreadsheet that analyzed all of those variables and came up with a score for the various bidders. Energenecs invited the people from La Crosse and Donohue to actually view the Sheboygan facility, so they would be familiar with equipment.

In early 2020 we went through this evaluation with Donohue and the owner, and they selected the HUBER Belt Dryer BT. The reason that they wanted to do this evaluation early was because they had to design a building around it. The engineer needed a head start to design the building, and all of the ancillary equipment that goes around the dryer, then finish their design work so they could bid it to contractors. The contractors saw our dryer in the building in Sheboygan so they knew what they had to install.

How has the HUBER Belt Dryer been working in Sheboygan?

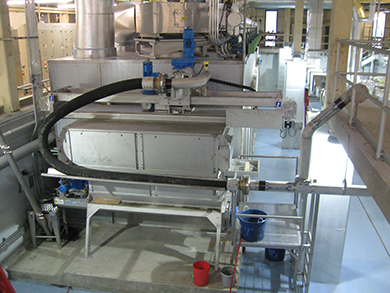

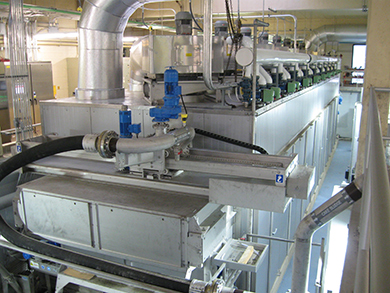

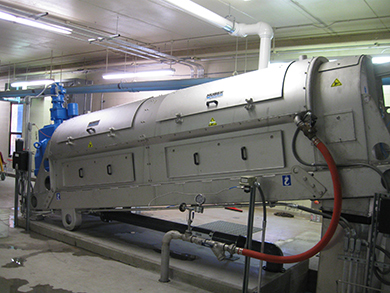

Energenecs sold a HUBER BT dryer for a throughput of 11,700 t/a in Sheboygan, Wisconsin, the first in the midwest (and second in the US) in 2014. The Sheboygan Regional WWTF treats an average of 18.4 million gallons per day (mgd) with a peak design capacity of 58.6 mgd.

The HUBER dryer was selected as a remedy to the biosolids storage shortage. The sludge that is produced as a byproduct of the wastewater treatment processes is anaerobically digested, dewatered, and then dried to a moisture content of less than 10%. The dryer utilizes biogas produced in the anaerobic digestion process and the waste heat from the plant’s micro-turbines to heat the dryer to approximately 204 degrees Fahrenheit. The final product is a pellet sized dry product that is a high quality fertilizer that is safe to use on lawns, shrubs, trees, flowers, vegetables, and as a general soil treatment.

The Huber belt dryer also allowed the City to enter a contract with Sure Gro, LLC to haul and beneficially reuse the dried biosolids. This allows the city to reduce the expense of applying fertilizer to farm fields by drying the sludge and selling it to a third party. This new process and the sale of biosolids will save the Sheboygan Regional WWTF an estimated $135,200 per year in operating cost in addition to meeting the biosolids compliance schedule.

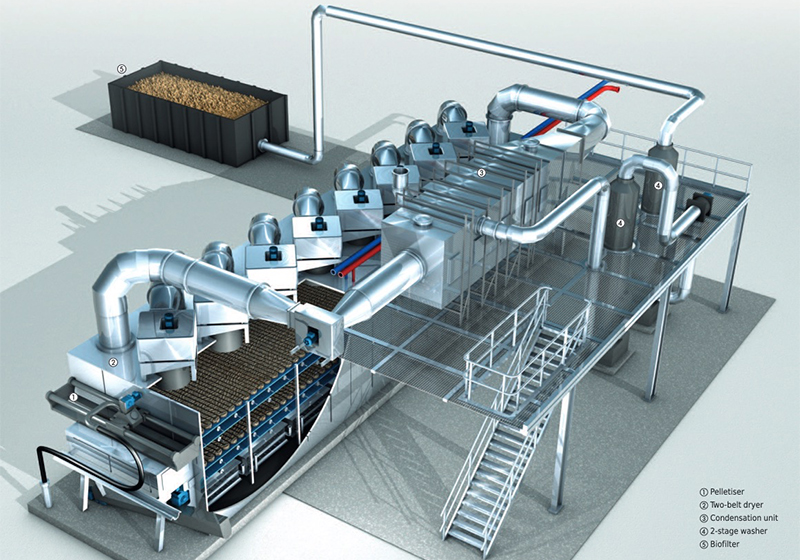

The feeding system of the dryer also ensures a reliable plant operation. The sewage sludge extruder, also called pelletizer, presses the sludge and produces spaghetti-like sludge strands with a defined surface-volume ratio. As the sludge keeps its form during drying it is possible to avoid the production of dust, the highest safety risk involved with the operation of dryers.

For more information contact Steve Berggruen at Energenecs.

0 Comments