Meet Brian Fuller, CAD Technician

.

Brian joined the Energenecs team this spring as a computer aided design (CAD) Technician. We asked Brian about his prior experience and current job at Energenecs.

What does a CAD Technician do?

Basically I take the Project Manager’s control system drawings and markups and make a set of schematics for our fabrication shop to build off of.

How did you get started in CAD?

I originally wanted to go into the Army, but found out late in my senior year of high school that they would not take me because I had open heart surgery when I was in kindergarten! So I went to a job fair, where I saw ITT Technical Institute offering CAD and ended up enrolling after graduating. I liked drawing, so that is how I chose CAD.

I worked at Powrtek Engineering after graduating from ITT. At Powrtek the CAD work was for wastewater treatment plants and lift stations, in addition to buildings, roadways and airports. I was at Powrtek for eighteen and a half years, until the owners decided that they were going to retire. My boss at the time knew Brian Akason (Technical Sales at Energenecs), who introduced me to Jared, the owner of Energenecs, and they offered me a job doing CAD.

What software do you use?

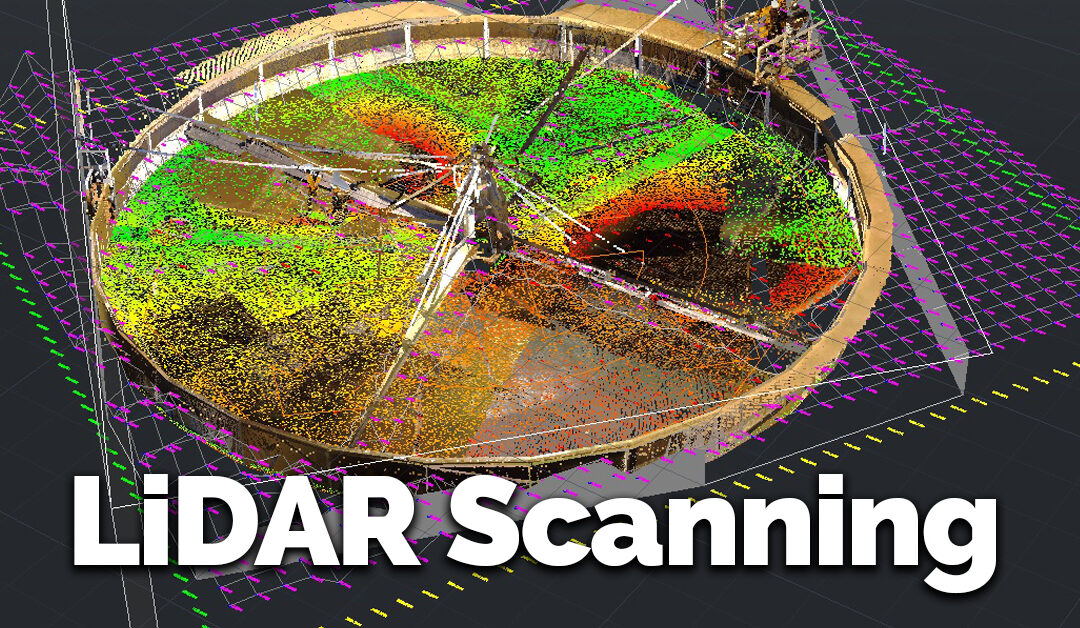

When I was at Powrtek, we were using AutoCAD and Revit, a 3d program. At Energenecs, we are using AutoCAD Electrical, which is really focused on wiring. You put your rungs in, and it will tell you what number it is supposed to be on when you drop a device in there. You can also pull a bill and materials list from the drawings.

What is the process for your projects?

The Project Managers will design the project per specifications. I CAD it up then it goes to the client for review. After the client approves the drawing, we make another round of changes, if needed, for the production release, then it goes to the shop. When the fabrication team is finished building a panel, they bring back the markups from the schematics, I make the changes that were made, and create the panel layout “as-built”. The final drawing layout is exactly how the panel is going to look when installed.

I work with Don Miles, a CAD Technician who has been at Energenecs since 2010 and have been learning a lot from him, the Project Managers and my boss, Brad Mentink. Work just flies by, it seems like when you get really into a project, the clock just keeps moving!

What is the typical size of the projects?

Some CAD projects are small, some are big. It could take a couple of hours to a couple of weeks to do them. The Village of Baldwin is a larger one, it has quite a few motor control centers (MCC’s) in it, so that project is going to take quite a while. Don Miles is working on that project.

What do you like to do outside of work?

My son and I like to mess around with remote control (RC) cars. We go hiking in the woods and we have these little crawler trucks that we bring with and drive them as we go hiking. It’s pretty fun, I have to admit! We also go to Washington Park Velodrome, it’s a bike track where we bring fast cars that we race.

Do you build RC cars?

Yes, I have built them or you can buy them, they are called Ready to Run (RTR). They are really fast, one of the cars goes about 80 miles per hour. They are 1/7 scale, about two feet long, though you can get them in all sizes. We also have boats, in addition to the cars and trucks. I was also into drones until I lost one! I don’t know if the electronics went bad on it, but it just kept going really high in the air and away from me and didn’t come back, then it fell somewhere. No more drones!

0 Comments