Revolutionizing Chain & Flight Sludge Collector Inspections

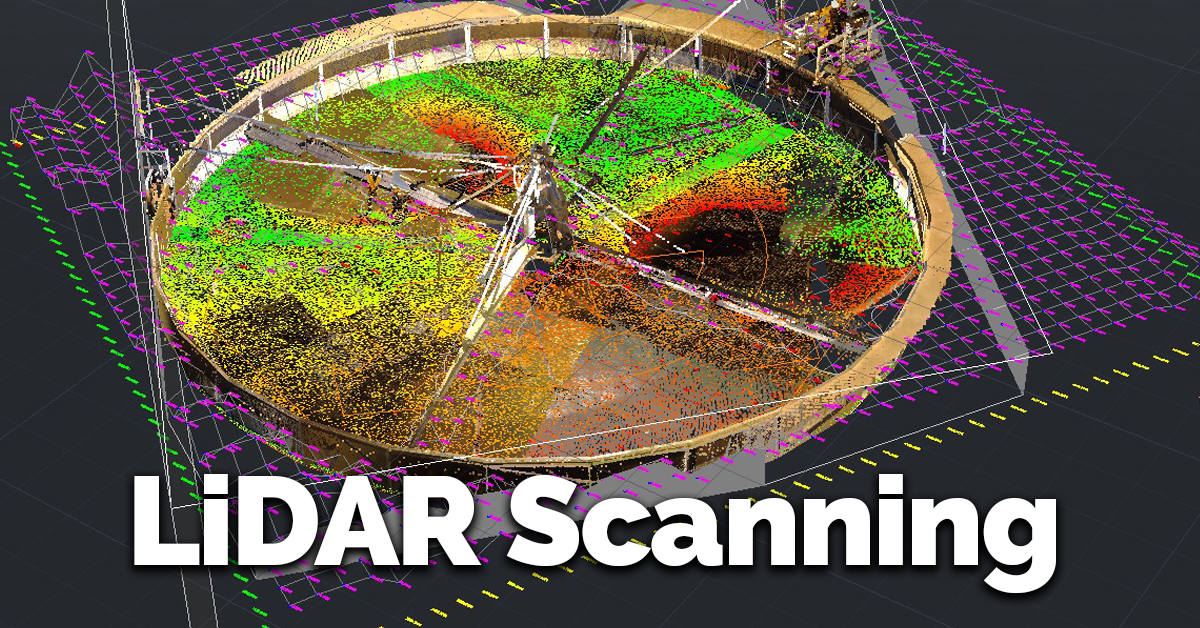

![]() Efficient sludge removal is essential for maintaining wastewater treatment plant performance. Over time, chain and flight sludge collectors experience wear that can reduce efficiency, decrease system capacity, and lead to costly failures if left unchecked. Traditional inspection methods can be time-consuming, expensive, and pose safety risks. With Brentwood Industry’s Tank Evaluation Program using LiDAR scanning technology, wastewater facilities now have a safer, more accurate way to assess basin conditions and optimize maintenance planning.

Efficient sludge removal is essential for maintaining wastewater treatment plant performance. Over time, chain and flight sludge collectors experience wear that can reduce efficiency, decrease system capacity, and lead to costly failures if left unchecked. Traditional inspection methods can be time-consuming, expensive, and pose safety risks. With Brentwood Industry’s Tank Evaluation Program using LiDAR scanning technology, wastewater facilities now have a safer, more accurate way to assess basin conditions and optimize maintenance planning.

What Is LiDAR and How Does It Improve Sludge Collector Inspections?

LiDAR (Light Detection and Ranging) uses laser pulses to capture high-precision distance measurements, creating detailed 3D models of physical structures. When applied to chain and flight sludge collectors, LiDAR scanning provides critical insights into the condition of key mechanical components.

Key Benefits of LiDAR Scanning for Chain & Flight Sludge Collectors

Unlike manual inspections that can be inconsistent, LiDAR scanning provides a high precision 3D model of the entire sludge collector system. To perform a LiDAR scan, the basin is drained, allowing for an unobstructed view of all in-tank mechanisms. The scanning system rapidly captures thousands of data points per second, producing an accurate digital representation of the collector system. This enables operators to:

- Detect mechanical wear on chains, flights, and sprockets before failures occur.

- Verify proper alignment of drive units and collector components.

- Monitor structural integrity over time for proactive maintenance planning.

- LiDAR scanning helps facilities stay ahead of maintenance needs, reducing the risk of compliance violations, unplanned shutdowns, and environmental penalties.

Following the evaluation, a detailed Polychem Solutions Report is provided that includes a review of the system’s condition including observations, photos, and recommendations. Any observed potential failure points or weaknesses will be specifically identified.

Case Study: LiDAR Scanning in Northern Illinois WWTP

A wastewater treatment plant in Northern Illinois processing over was experiencing issues in its chain and flight sludge collector system. To diagnose the issue, Brentwood deployed a LiDAR scanning system after draining the basin. The scan revealed : “Several of the shafts in this basin had worn through their bearings and were damaging the shaft/bearing housings, leading to problems in starting the collectors”

Striations on drive chain evidence of grit wear; uneven wear pattern evidence of misalignment.

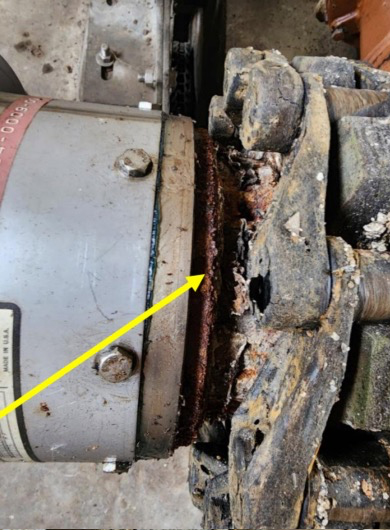

Corroded hub connecting torque limiter with 11T sprocket.

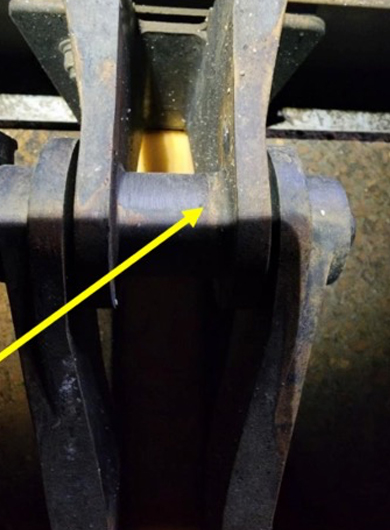

Flight passing around tail shaft unevenly/torqued around shaft evidence of chain skipping on sprocket teeth.

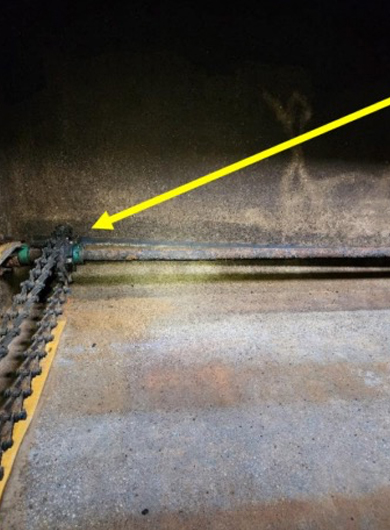

Completely unworn shoulder on one side of collector chain evidence of misalignment.

Adjustable take-up on upper idler shaft for tensioning purposes; heavily corroded take-up likely no longer functions as intended.

Bearing housing centerline compared to upper idler shaft centerline.

The Future of Sludge Collector Inspections

While LiDAR scanning requires tanks to be emptied, its ability to deliver precise mechanical assessments makes it an essential tool for modern wastewater facilities to improve system reliability, extend equipment life, and reduce long-term costs. Lidar scanning is an extremely capable tool when performing inspections, and in conjunction with having an expert in chain and flight clarifiers on-site is capable of addressing your chain and flight clarifier concerns. LiDAR scanning can also be applied to trickling filter media. Note LiDAR is used in some applications of this technology, while laser scanning is the primary basis of this technology.

Schedule a LiDAR Scan for Your Chain & Flight Sludge Collector

Contact Energenecs to schedule a LiDAR scanning to potentially enhance efficiency, safety, and cost savings for your chain and flight sludge collectors.

0 Comments