Mixer Solves the Icing Problem!

When managing water tanks and towers, especially in colder climates, preventing ice formation is a critical concern. Ice can cause damage to tank appurtenances such as ladders, cathodic protection systems, fill & drain piping, etc. or in extreme circumstances even cause catastrophic tank failures. To combat this, utilities are increasingly turning to tank and tower mixing systems, which keep water circulating and ensure even temperature distribution throughout the tank. We asked Michael Dello Iacono from Clearwater1, the leading manufacturer of technologies used to improve water quality in storage tanks and distribution systems, about their PAX Mixers and how they prevent icing in water tanks.

How do mixers prevent ice formation?

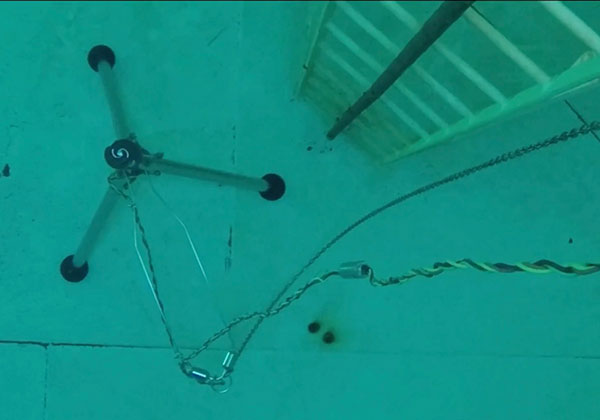

The most effective systems for preventing ice formation are those that incorporate advanced mixing technologies specifically designed for these challenges. Clearwater1’s PAX mixers help maintain uniform water temperatures, ensuring that cold water layers do not form at the top of the tank, which can lead to freezing. Ice is less dense than water, and tends to form at the air water interface at the top of the tank during the night when air temperatures are coldest, and water use is low. When Ice forms at the top of the tank, it can form an ice bridge, with Ice adhering to the sides of the tank and extending across the entire water surface, When tanks experience a rapid water draw down in the morning as customers wake up and take a shower or run the dishwasher, etc., an air gap can form under the ice shelf. Later in the morning, as the sun starts to warm up the tank shell, the Ice sheet can break loose and collapse. These types of events can cause significant damage to anything that is inside the tank, ripping appurtenances away from the tank walls, causing coating damage or even puncturing the tank walls.

Customization Based on Tank Type and Size

The type of tank—whether it’s elevated, ground-level, or even underground, influences the design of the PAX mixing system. Elevated tanks, which are more exposed to temperature fluctuations, often require more robust mixing solutions to prevent ice formation. For remote water towers where power supply can be a challenge, Clearwater1 offers solar-powered mixing systems.

Beyond ice prevention: Improving water quality and reducing THMs

While preventing ice formation is a function of these systems, they also play a critical role in maintaining water quality. Many water utilities add disinfectants, such as bleach, to their water supplies, which can create trihalomethanes (THMs)—disinfection byproducts that are regulated by the EPA. Mixing ensures that the water does not become stratified, reducing the chances of THM formation by circulating the water evenly throughout the tank. Without mixing, the water can sit stagnant, leading to temperature layers within the tank—much like a pool where the surface is warm, but the bottom is cold. Stagnant water increases the risk of ice formation in cold climates and higher THM levels, which can trigger compliance issues for utilities.

How Do PAX Mixing Systems Differ from Others?

Several factors set these mixing systems apart including the design, engineering, and longevity that make their systems particularly effective. Cleanwater1 also offers a trade-in program, allowing customers to exchange their old mixers for discounts on new ones, a unique feature that acknowledges the equipment’s lifespan, which can range from five to fifteen years, depending on the operating conditions and usage. Cleanwater1’s extensive experience, coupled with their customized systems, positions them as leaders in the industry.

PAX Jet Mixer

PAX Impeller Mixer

PAX Horizontal Mixer

Tank Shark Eductor Mixer

Why Don’t All Utilities Use Mixing Systems?

Despite the benefits, not all utilities mix their tanks, which may seem surprising considering the PAX mixing systems are relatively inexpensive when considering their long-term benefits. Depending on the project, costs can range between $20,000 and $60,000, which is a small investment when compared to the potential savings from avoiding damage and regulatory fines.

A Vital Tool for Water Utilities

Tank and tower mixing systems are not just about preventing ice—they are about maintaining water quality, reducing THMs, and ensuring operational efficiency. For utilities operating in colder climates or using disinfectants in their water supply, investing in a reliable tank mixing system can save costs in the long run by preventing structural damage and compliance issues.

With thousands of installations worldwide, the PAX family of energy-efficient mixers is recognized for their compact design and low maintenance, ensuring easy installation. In fall 2024, Energenecs will provide a ground level PAX mixing system to Oak Creek in Milwaukee County this fall.

For more details on these mixing systems, contact Emily Vebber at Energenecs at 262-377-6360.

0 Comments