Top 5 Ways to Optimize Wastewater Dewatering

Why Optimize Wastewater Dewatering?

A wastewater dewatering system that is not optimized can cause headaches with higher maintenance and costs, lower throughput, less dry cake solids, and cloudy effluent. Our experts provided top five tips to optimize wastewater dewatering systems:

- Rebuild or restore existing equipment

- Simplify by replacing existing technology

- Optimize polymer usage

- Replace or repair pumps

- Update controls and instrumentation

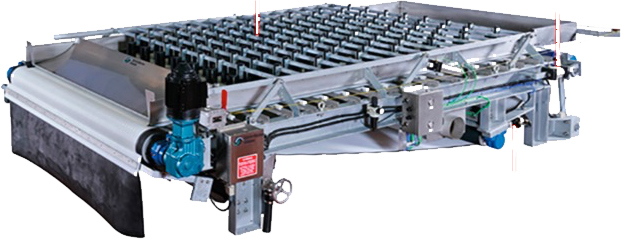

1. Rebuild or Restore Equipment

After five or more years, performance degradation can occur with your dewatering equipment. Restore performance with maintenance, rebuild or replacement of most common belt technologies by Charter Machine Company.

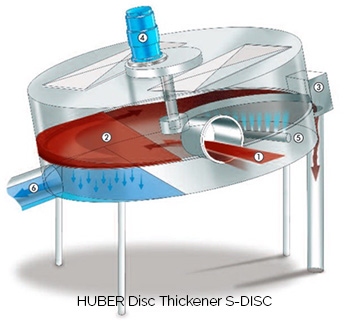

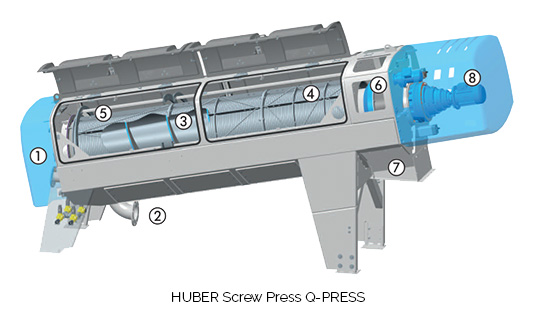

2. Simplify by Replacing Existing Technology

Looking to replace belt technology altogether? Ask us how HUBER Technology’s S-Disk disc thickener and Q-press screw press might be the solution. Read about our Disc Thickener pilot study in Sister Bay.

3. Optimize Polymer Usage

Polymer optimization can not only reduce polymer costs but can also lead to a better biosolids product and reduced transportation costs. Energenecs provides on-site testing and evaluation services to determine optimal polymer selection and dosage.

Reduce polymer usage with the UGSI Chemical Feed Solution‘s Polyblend® Polymer Activation Systems MAGNUM mix chamber which increases polymer activation efficiency by more than 20%! Key features of the MAGNUM mix chamber :

- High Energy/Low Energy Mixing Profile. Ratio of low‐to‐high energy mix zone volume was increased to increase residence time (Ꚍ) High‐energy mixing at the moment‐of‐initial‐wetting (MOIW) to achieve maximum hydration (high viscosity) of the polymer particle in the shortest time

- Direct-coupled 3,450 RPM motor, eliminates the need for shaft alignment

- Quick Disconnect on the neat polymer injection check‐valve, eliminates the need for tools to access the check‐valve for periodic cleaning

4. Replace or Repair Pumps

The most common problems related to dewatering involve low suction or flow rate. The Wangen series of progressive cavity pumps for wastewater treatment are ideal for polymers, sludges and high solids apps, and are fitted with cardan joints with sleeve protection, making the pumps resistant to clogging and wear. The unique design also allows simplified maintenance to maximize the life of your investment.

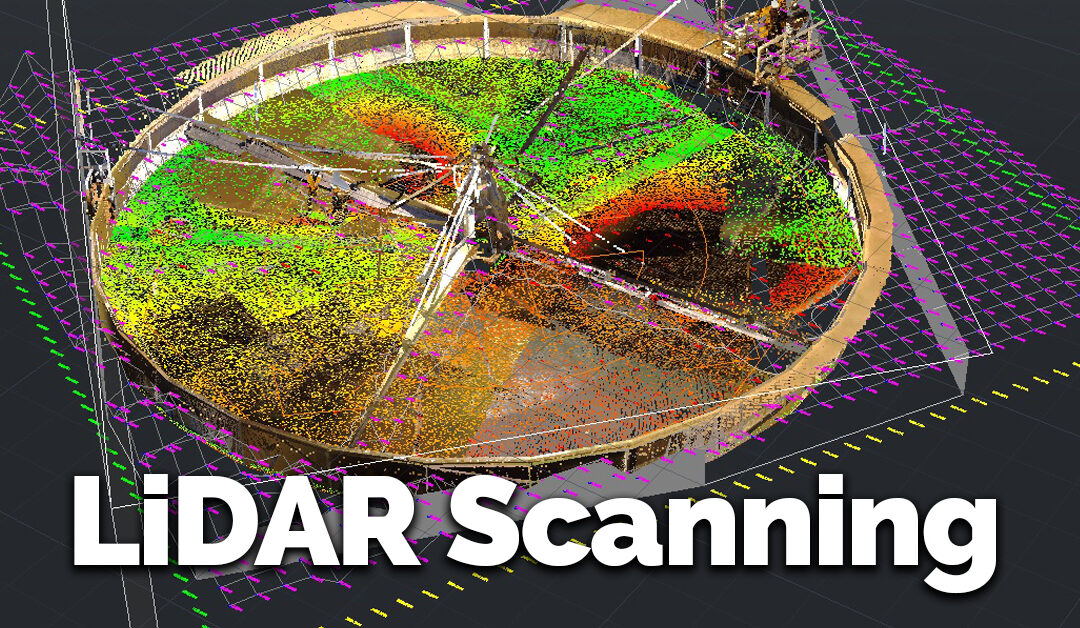

5. Update Controls and Instrumentation

Real-time control solutions from Energenecs can optimize wastewater dewatering systems and can make plant operations easier and more reliable.

FREE dewatering system evaluation

Contact Dan Waala of Energenecs for a free evaluation to help optimize wastewater dewatering. Dan brings extensive experience in the wastewater industry. He has been a wastewater operator for the City of Brookfield, the City of Waukesha and most recently, the plant supervisor for the Village of Jackson.

0 Comments