What you Need to Know about PFAS

Per- and polyfluoroalkyl substances (PFAS) are chemicals that resist grease, oil, water, and heat. They were first used in the 1940’s and are now in hundreds of products including stain and water-resistant fabrics and carpeting, cleaning products, paints, and fire-fighting foams. Certain PFAS are also authorized by the FDA for limited use in cookware, food packaging, and food processing equipment.

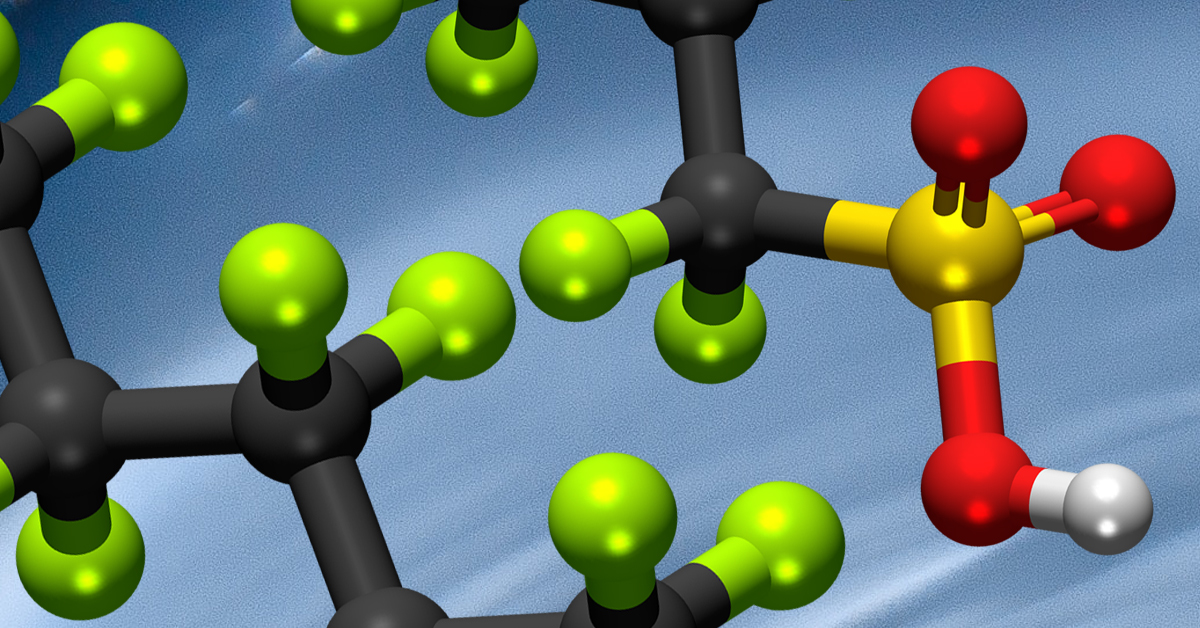

Chemically, individual PFAS can be very different. However, all have a carbon-fluorine bond, which is very strong and therefore, they do not degrade easily, earning their nickname “the forever chemicals”. The widespread use of PFAS and their persistence in the environment means that PFAS from past and current uses have resulted in increasing levels of contamination of the air, water, and soil. Accumulation of certain PFAS has also been shown through blood tests to occur in humans and animals. While the science surrounding potential health effects of bioaccumulation is developing, exposure to some types of PFAS have been associated with serious health effects.

Proposed PFAS National Primary Drinking Water Regulation

On March 14, 2023, EPA announced the proposed National Primary Drinking Water Regulation (NPDWR) for six PFAS including perfluorooctanoic acid (PFOA), perfluorooctane sulfonic acid (PFOS), perfluorononanoic acid (PFNA), hexafluoropropylene oxide dimer acid (HFPO-DA, commonly known as GenX Chemicals), perfluorohexane sulfonic acid (PFHxS), and perfluorobutane sulfonic acid (PFBS).

We spoke to Jim Groose, Senior VP of Business Development at WaterSurplus, located in Loves Park, Illinois. Jim is an expert in water chemistry, groundwater treatment, municipal water treatment, and activated carbon and filtration. We asked him about current options for removing PFAS in water.

What is the current status of PFAS?

I believe that there’s 5,000 or more of these different PFAS molecules, but the proposed regulations are only for six! I think they will be adding more in the next couple of years. In the US they stopped manufacturing the two worst ones (PFOA and PFOS), but they still make them overseas. Some of the waterproofing products that end up on textiles that are made overseas and there’s no regulation on that, we can import it, but we can’t produce it.

What are methods to remove PFAS from drinking water?

You can use a pressure filter, using an appropriate adsorption media, that will take the PFAS out. There are a couple different filter media that work: granular activated carbon and anion exchange resin.

When you filter for iron and manganese, you try to oxidize the iron manganese, then filter out a particle. What’s different when removing an organic material like a PFAS molecule, it’s more of an absorption or ion exchange process. You can use granular activated carbon which has a lot of absorption space in it. They have all these graphite plates and there’s a space between those plates of graphite and organic molecules will just slide in there. It keeps the molecules in there because they’d rather stay there, than in the water. That’s what granular activated carbon does. Anion exchange resin turns out all the PFAS molecules, one of two functional groups at one end of the molecule, and that’s either a carboxylic acid group or a sulfonic acid group. Each of those carbon bonds -OH, and when it’s in water, the H+ comes off. And it’s an anion O- (a negatively charged ion) in solution. An anion exchange resin is very efficient at removing them from water, so they’re really an adsorption media.

What is the PFAS removal procedure?

So with both of these methods you put this brand new media in filter vessels and run the water with PFAS in it, and you get non-detectable PFAS water out. When PFAS starts to show up in the effluent, they call that “breakthrough”, and what you have to do is to remove media and reactivate the granular activated carbon or if using anion resin exchange incinerate or landfill it in a hazardous waste facility.

What are the other differences between the granular activated carbon and the anion exchange resin removal methods?

It turns out there are some big differences in how each of them perform. And I’ll talk about granular activated carbon first.

Removing PFAS with Granular Activated Carbon

The first ten years of my career, I worked at Calgon Carbon Corporation. I started out in R&D, then ended up in technical sales. I really got to understand activated carbon very well during that time. Activated carbon is what you typically would use to remove organic compounds from water and I think more communities and engineering firms use granular activated carbon as their treatment technique just because of familiarity that goes back 55 years. Activated carbon was the preferred way to remove that because they figure organic molecules that’s the only way to get them out as something that has a lot of surface area and has that absorption energy to grab it.

Activated carbon likes bigger molecules. So, bigger molecules are held more strongly than smaller molecules. There are literally thousands of molecules that have different carbon length. You could have 3, 4, 8, 10 or 12 carbons, and then fluorinate all those carbons, instead of adding hydrogen on them. Carbon fluorine bond is one of the strongest bonds in nature, it’s a hard one to break. That’s why you can’t remove it very easily by oxidizing or thermally destroying it. Activated carbon really likes the seven or eight chain carbon or longer chains the best. As for the shorter chains, it doesn’t hold them quite as well.

What is the difference between long chain and short chain PFAS molecules?

The human body excretes these compounds if they’re short enough. Your kidneys have a permeable membrane, and the shorter chain ones your body can pass through those membranes in your kidney. The longer 6-7-8-10-12 carbon chains are so big that you don’t excrete them, and they stay in your body, and they don’t break down. That’s why for the longer chain ones, they’re setting lower limits for exposure in the EPA regulation. While the shorter chain molecules might breakthrough earlier, it turns out they aren’t as toxic. It still looks bad when you still detect some PFAS, even if it’s the shorter chain ones.

What are the advantages of using granular activated carbon?

One advantage is that it is less expensive than the anionic resin, about three to four times less expensive. We’re talking $75-90 per cubic foot for that media, versus resin which is $325 a cubic foot. There’s also several companies that make granular activated carbon here in the United States and they have reactivation facilities, where they could take back the spent carbon when they’re done.

When you want to reactivate your granular activated carbon it needs to be shipped by truck to reactivation facilities in Pennsylvania, Texas, or California. They put it through a high temperature reactivation process where they push all the PFAS off of the granular activated carbon and thermally break it down, so they have an afterburner on those reactivation furnaces, and they get like 99.9999% removal or destruction or the PFAS.

What are the disadvantages of using granular activated carbon?

If there’s one bad news about using granular activated carbon, they preferentially hold the longer chain molecules. It might hold those in certain applications for a couple of years but some of the shorter chain ones may hold on a little bit of what they call breakthrough. They may breakthrough in nine months or so. Another disadvantage is that you need bigger vessels which means you need more activated carbon to do the normal job of removing PFAS.

How is the vessel size determined?

When you design a removal system, you want to know how big of a vessel you will need. They use a design method called “empty bed contact time” to determine how big the vessel should be and how much granular activated carbon should be online. The textbook number for granular activated carbon is a minimum of 10 minutes of empty bed contact time (EBCT).

When you use anion resin it’s four times more expensive, but it’s five times more effective. You only need to design two minutes of EBCT. What we’re doing in our systems right now is designing a two and a half minute empty bed contact time, I’ve got a little extra capacity in there for removing the PFAS.

The second thing is when you design a permanent facility you’ll usually design it with two vessels in series. The reason for that is the reactivation processes are expensive enough that if you just put one vessel there and let it start to breakthrough, you have not used about 20% of the capacity of the media that it could hold. By having a second one after it, you can let the first vessel breakthrough all the way to what the raw water looks totally saturated and use 100% of the removal capacity. Then you reverse the flow in this lead lag vessel system. Then you input water through the second vessel first, and change out that media, put new media in the first, and alternate back and forth down the road. Over a matter of four or five change outs, you pay for the second set of vessels, that polish vessel, because of the extra capacity you get by being able to let the first vessel breakthrough.

How often are the media change outs?

It’s a combination of some of the chemistry of the water in general, what other organics might be in it, how high the level of PFAS is and which PFAS types are there. There’s a prediction program you can use to help predict how long it might last. You can also run pilot tests, though one of the problems with the pilot tests is they frequently don’t breakthrough for a year. That’s a really long pilot test!

What are the advantages of PFAS removal using anion resin exchange?

The shorter chain molecules are removed very well by the anion resin. If you want to remove it with granular activated carbon that might breakthrough in six months.

One of the big advantages of the anion resin is the little 3, 4, 6 carbon chain, they’ll take all those compounds out of the water and last three to five years, instead of one and a half to two, even though you’re putting less of it online.

How long has the anion resin been around?

In resin, it’s been used to remove anions for 50 years. They can change the functional groups on the resin to remove anions, then in addition, they can change what anion characteristic it has, to enhance its ability to remove longer chains. So they’ve really refined the anion resin in the last 10 years to remove organic materials, anion characteristic and so they tweak that anion resin a little bit to make it even better. Making resins is kind of a complicated, organic process you might say and has some waste associated with it. All of these resins are made overseas which is a little bit of a drawback.

Can you regenerate the anion exchange resin?

Right now you can’t regenerate the anion exchange resin. So either landfill it in a hazardous waste landfill or send it to a high temperature furnace where it’s incinerated. A high temperature run has demonstrated 99.9999% removal efficiency. There are half a dozen of those facilities throughout the United States. There isn’t an incineration facility in Wisconsin or Illinois currently, but there is one in Nebraska and in Colorado.

How do you determine the best system to use?

As a supplier of PFAS removal systems, you try to help determine what’s going to be the most economical way to treat for PFAS in the next 30 years. It really depends on what species are present and how much total organic carbon is in the water. The natural organic compounds that might have a characteristic to it that will consume with some of that in the anion resin or take up some of that in adsorption space in the granular activated carbon that we try to help with that analysis.

We work with the engineers that the community hires to help with figuring out the cost of the treatment equipment, if you do it with carbon or with resin. And then we talked to the different disposal methods and the media suppliers. And we get the cost of the media and the cost to dispose of the media when it’s done. And then you can compare over a 30 year period, which one’s really going to be the most economical and I think, right now, two out of three facilities being built are designed with granular activated carbon. Only one out of three are being designed with resin but I think more of them are being designed with carbon just because they’ve got more familiarity with that from 50 years of history of using it to remove organics. I think probably more facilities deserve to be designed with anion resin. We can build either kind.

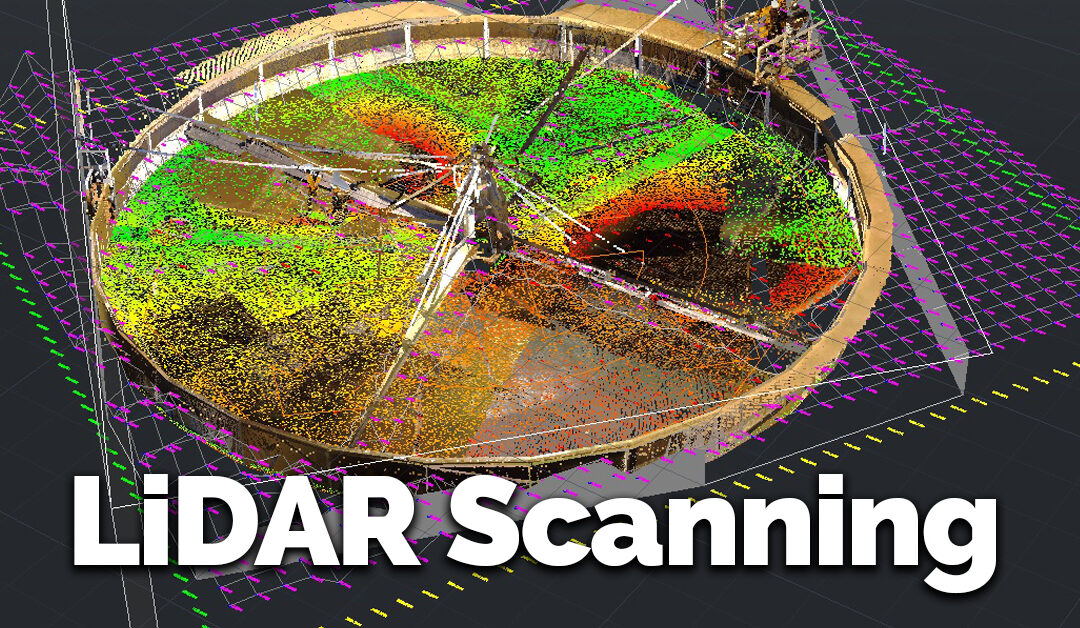

The one thing that we do that’s a little bit different is determine what you’re going to do for the long term, and that is at least a two year process. Most engineers want to do pilot studies that compare resins to carbon but studies may take six to nine months to run. And then you can crunch these numbers and see which one might be most economical. Then the engineering firm has to design the treatment equipment and building to house it in and that’s another six to nine month process.

They have to submit the design to the state of Wisconsin for their review and approval which is a 90 day process. When those are approved it’s usually a one month bidding process or maybe another two to four week evaluation process. When the contractor wins the bid, add on another nine month to one year process to build. You have to work really fast to pull that off in two years! It is more like two and a half years.

What are short term options to remove PFAS?

If you detect the PFAS in your water, there’s really two different things you can do right now: one is you could shut that well down. But then your total capacity for your community for producing water is going to go down because you lost the well. Some of the communities have plenty of wells and you always want to add some excess capacity. But for smaller communities, they can’t afford to have too much extra capacity, because all that costs money. So it’s harder for them to just turn that well off.

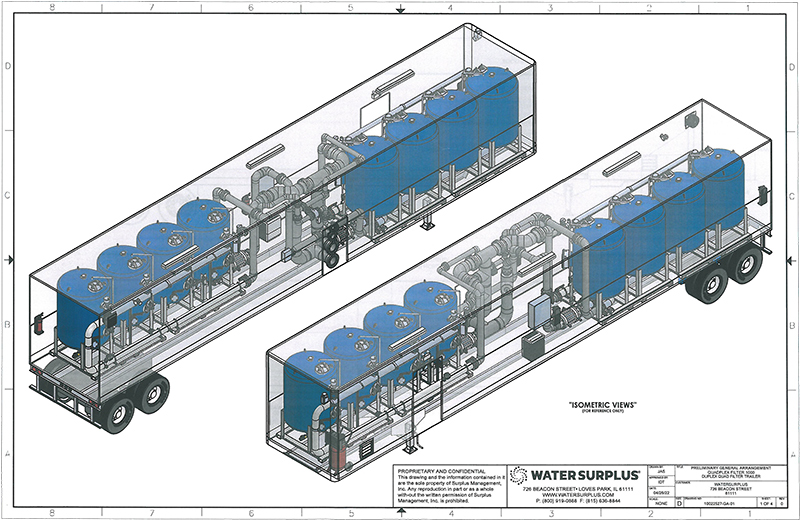

The second option is renting a temporary system. One of the services WaterSurplus provides is equipment to use now from our rental pool. We already have three projects here in Wisconsin that are currently renting. We have pressure vessels and anion resin in stock. So our temporary treatment can buy you time and keep water production capacity up.

Which system is used for the PFAS removal rental?

We use the anion resin because that’s five times more efficient and also use fewer vessels than if we tried to do what with granular activated carbon. We can also get approval from the state in about a month to put in a temporary system until the full scale system is designed.

We have two currently installed in Wisconsin and western Wisconsin and we have a contract to build a third one for Marshfield Utilities. In their case, they want to use the temporary treatment for five years. They asked us to build something for them and let them purchase that. And then in five years they think they’ll have the budget to build a full scale system and retire this temporary system.

The temporary systems are not doing the lead lag. We’re only providing one vessel because they usually last about two years and that’s how long it takes to implement a new plan. So that’s one reason why our rental solutions are less expensive. We also use resin which is five times more efficient and you shouldn’t have to change the media as often.

What about the wastewater side of it?

The next nut to crack is going to be on the wastewater. My head explodes when I even think of it! Every community in the United States collects all sorts of PFAS at the wastewater plant because we wash off all sorts of products that contain it and it ends up in wastewater discharges and in the municipal wastewater sludges where it’s mobile and toxic. At some point WWTP’s may be required to treat their final wastewater going out. But what I think is going to be a bigger problem is the municipal sludge that is spread on farmer’s fields. Sludge contains phosphorus, which helps plants grow and it is a good way to get rid of it by spreading it on farmers’ fields. The problem is, it is contaminated with PFAS. We will have to deal with sludge differently, by incinerating or landfilling it. But the wastewater side is going to end up having regulations, though it’s a different animal than drinking water.

What do you predict the future of PFAS will be?

National Rural Water sued 32 manufacturers of PFAS and recently won a multibillion dollar judgment. The communities that have signed up as part of that can apply for some of that funding to help pay for cleanup. The perpetrators of all these compounds are starting to contribute because there are dozens of lawsuits out there collecting money for remediation. And once enough of them keep winning, the manufacturers are going to stop making the compounds and do something else because it’s too costly. I’m hoping in 10 years, basically they’re not making PFAS anymore and we are just cleaning up the last 40 years.

Contact our team for more info

about PFAS removal from drinking water.

0 Comments