Energenecs to supply controls for Wisconsin’s largest PFAS removal system

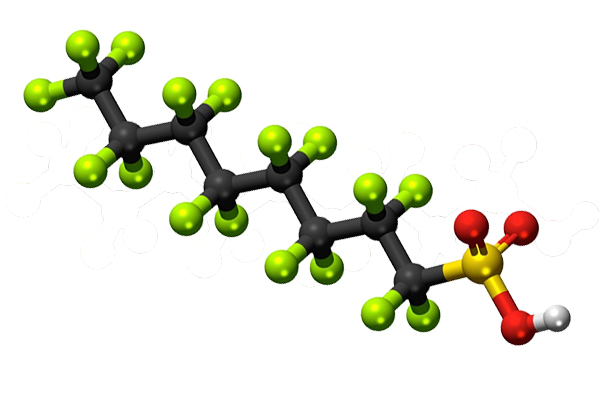

With concerns growing over PFAS, a group of man-made chemicals found in everything from carpets to firefighting foams, the City of Eau Claire is stepping up to ensure safe drinking water for its residents. Known as “forever chemicals” because they don’t easily break down, PFAS have been linked to health risks, prompting the city to take action.Detecting and Tackling PFAS

Eau Claire Water started testing for PFAS in mid-2020 and found levels initially below recommended standards. However, new guidance from the Wisconsin Department of Health Services in June 2021 led to more stringent testing. By July 6, 2021, four of the city’s fifteen wells were found to have PFAS levels exceeding safe standards. These wells were shut down, and the city switched to using eleven wells with safer PFAS levels.

Long-Term Solutions and Upgrades

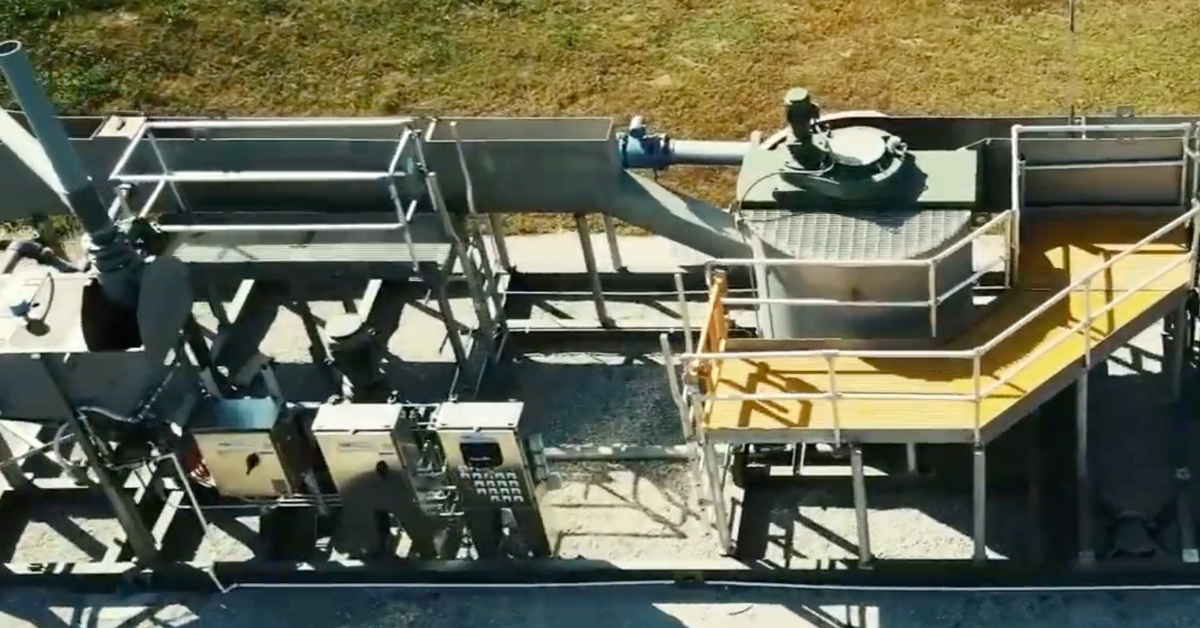

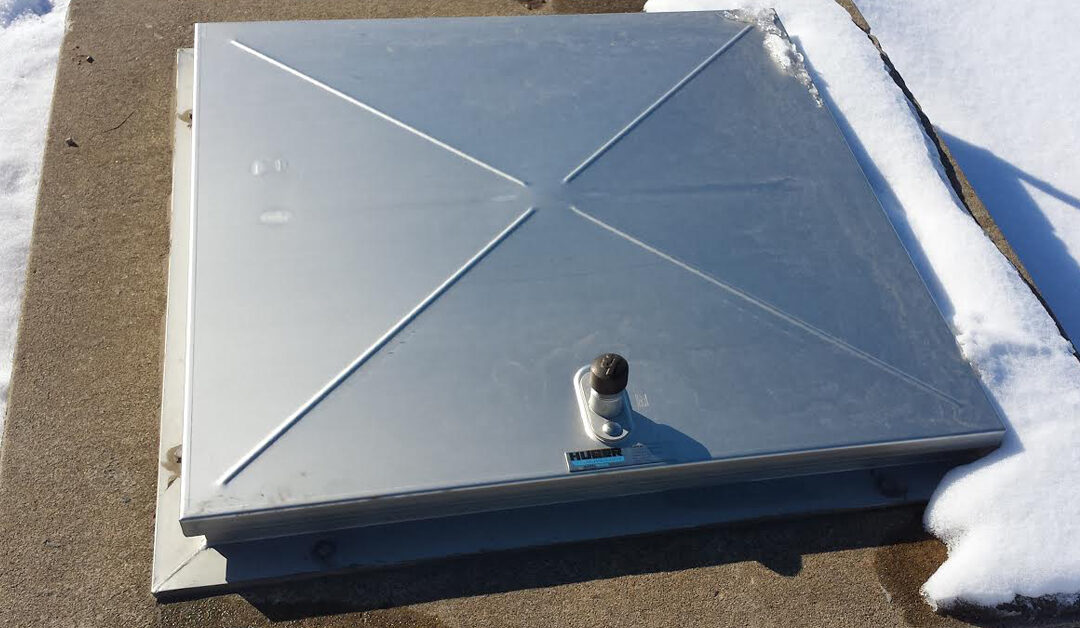

Eau Claire is committed to solving the PFAS issue with a variety of approaches. These include directing water from higher-PFAS wells into absorption ponds to prevent contamination spread and partnering with the Wisconsin Department of Natural Resources to explore long-term solutions like new wells and advanced treatment methods. In 2023, pilot testing showed that Ion Exchange technology was the best method for removing PFAS. The city teamed up with Gannett Fleming to design a new PFAS removal facility, set to be the largest in Wisconsin, at the water treatment plant. Construction is planned to start in summer 2024 and will take about 18 months, with a budget of around $20 million. The project is funded through the City’s Capital Improvement Plan, the Safe Drinking Water Loan Program, and federal grants.

Eau Claire is committed to solving the PFAS issue with a variety of approaches. These include directing water from higher-PFAS wells into absorption ponds to prevent contamination spread and partnering with the Wisconsin Department of Natural Resources to explore long-term solutions like new wells and advanced treatment methods. In 2023, pilot testing showed that Ion Exchange technology was the best method for removing PFAS. The city teamed up with Gannett Fleming to design a new PFAS removal facility, set to be the largest in Wisconsin, at the water treatment plant. Construction is planned to start in summer 2024 and will take about 18 months, with a budget of around $20 million. The project is funded through the City’s Capital Improvement Plan, the Safe Drinking Water Loan Program, and federal grants.

Teaming Up with Energenecs

A crucial part of this project is the collaboration with Energenecs, who will provide the controls for the PFAS removal system. They will provide the overall monitoring and control system for the project.

Energenecs will provide:

Design coordination and Implementation of Control Systems:

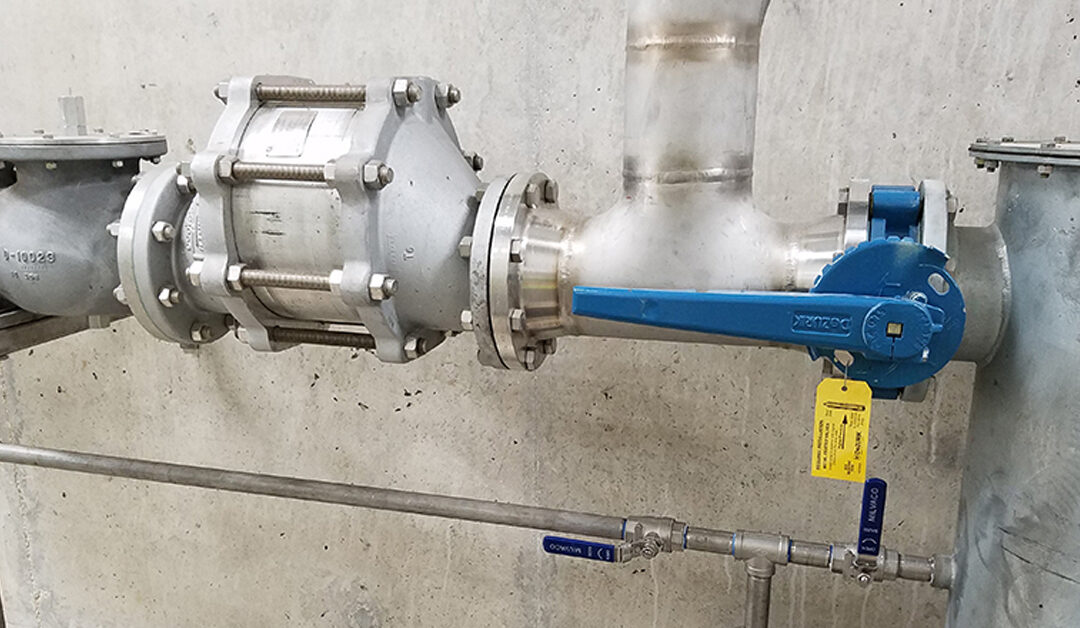

- Supply of various control panels including the new Main Process Control Panel SCADA Room (PCP-PFAS) and existing Process Control Panel.

- Assembly of UL508A control panels

Software and Programming:

- Programming of Allen Bradley PLC control logic for valve position and flow control, chemical dosing calculations, and critical chemical tank level monitoring

- Development of graphical applications using AVEVA Wonderware SCADA software for monitoring, alarming, trend analysis, and data logging.

Instrumentation and Monitoring:

- Supply & field calibration of large raw water magnetic flow meters, pressure transmitters, and radar chemical tank level transmitters

Testing, Commissioning and Field Support:

- Formal shop testing (witnessed) of control panels and SCADA software.

- Coordination with electrical contractors for field wiring verification.

- Field startup, acceptance testing, and calibration of instrumentation

- Operator, maintenance, and supervisor training sessions

0 Comments