UGSI Polyblend Case Studies

Energenecs put UGSI Polyblend units to the test in seven separate Polyblend case studies throughout Wisconsin and Illinois.

Case Study #1

Best Cake Solids AND Lowest Consumption of Polymer

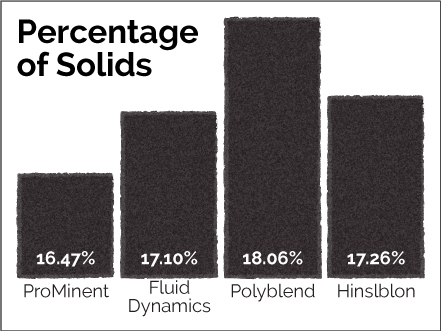

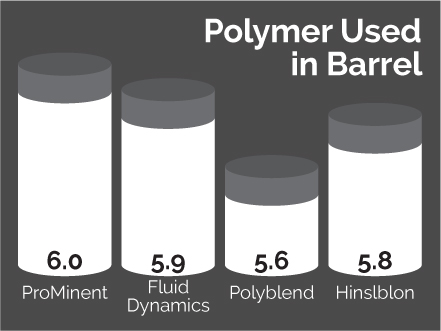

Energenecs trialed the UGSI unit for one week In Baraboo, Wisconsin for a head to head test versus Velodyne, Fluid Dynamics, and Hinslblon in one of our Polyblend case studies. Shown below are the results of identical trials showing UGSI produced the best cake solids while consuming the lowest amount of polymer. The unit was installed with a new centrifuge upgrade for the facility and has been a success, there has been no need to revisit site since startup.

Case Study #2

Cake Production Exceeded Expectations in Polyblend Case Studies

In Dousman, Wisconsin Energenecs installed a UGSI PolyBlend MM Series which included a complete Energenecs-HUBER dewatering system. Part of a package featured the HUBER Q620.2 Screw Press, Energenecs Controls, Wangen Pump, and UGSI MM Series. The cake production has exceeded expectations at dewatering from 1.5% sludge to 22% cake.

Case Study #3

Successful Polymer/Dewatering Startup in New Facility

An installation of the UGSI PolyBlend MM Series by Energenecs was included in a complete dewatering system in Carter, Wisconsin at a brand new facility, The community had never worked with polymer/dewatering applications before, though after training, operators were able to grasp understanding of the unit with ease. The unit has been working successfully since startup.

Case Study #4

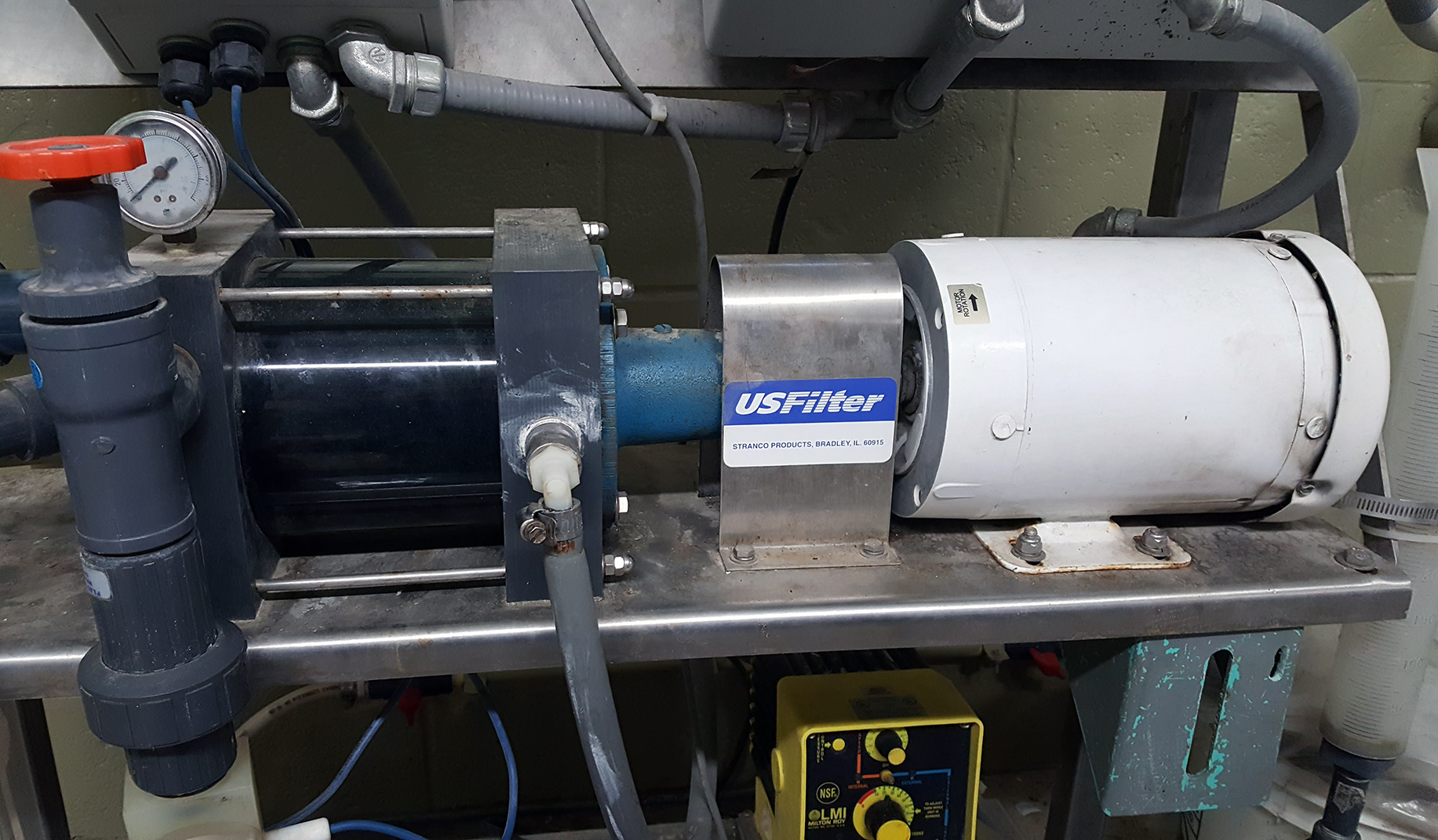

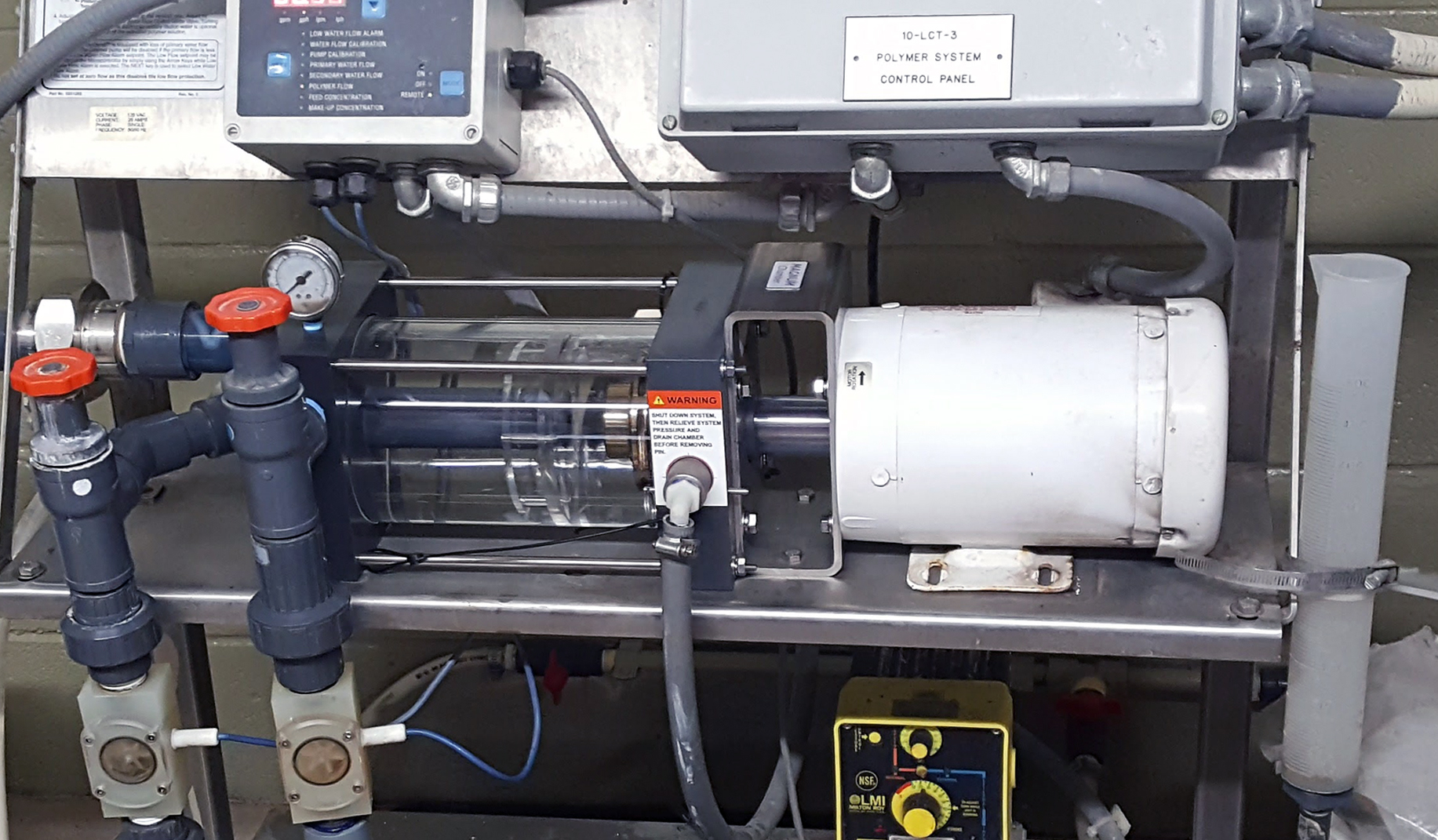

Retrofit Produced 15% Polymer Savings

A UGSI Magnum chamber retrofit was done on an older model of PolyBlend (when it was under the US Filter brand name) by Energenecs. The facility in Grafton Wisconsin upgraded their mix chamber via a simple changeout process (demonstrated in photos) to achieve 15% polymer savings.

Case Study #5

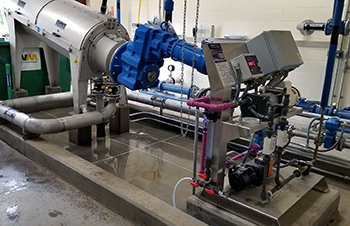

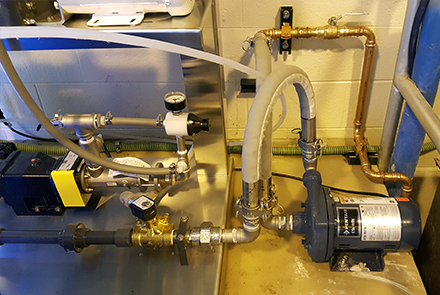

Aging Polymer Tank Added to Condition Polymer Solution

Two UGSI PolyBlend MM Series units were supplied to a centrifuge upgrade at the Itasca, Illinois WWTP. Energenecs also supplied a polymer solution aging tank skid to condition the polymer solution further, as typically practiced with the hybrid cross-linked emulsion polymers used in centrifuge applications. The aging tank was outfitted with Wangen Pumps, a variety of E&H instrumentation, and Energenecs controls.

Case Study #6

Optimized System on a Bench Scale

An old US Filter PolyBlend unit at Johnsonville Sausage was replaced earlier this year by Energenecs. Polymer testing was conducted on site prior to installation on a service trip to demonstrating Energenecs’ ability to help optimize systems on a bench scale.

Case Study #7

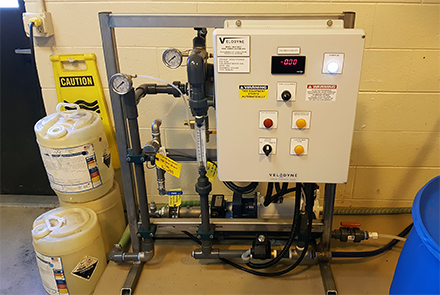

UGSI Polyblend vs. Velodyne saw 20% Improvement

The UGSI Polyblend was trialed by Energenecs in a head to head comparison versus Velodyne in Saukville, Wisconsin. They saw a 20% improvement versus the Velodyne during the trial period of one month. Later Energenecs installed a new mixing valve at a more appropriate location; the existing location was too far from the belt press and floc was breaking up. The cake was improved by 2% and further decreased polymer consumption.

For more information about these studies, contact John Yanisch at 262-377-6360 or click on button below to email:

0 Comments