HUBER S-Disc Sludge Thickener System is Becoming Popular in Wisconsin

Energenecs recently completed another HUBER S-Disc sludge thickener system for the City of Medford, Wisconsin this summer. The S-Disc is becoming more popular throughout the state for its small footprint and performance. We spoke to Steve Berggruen at Energenecs about this innovative technology.

What were the goals for the

City of Medford WWTP?

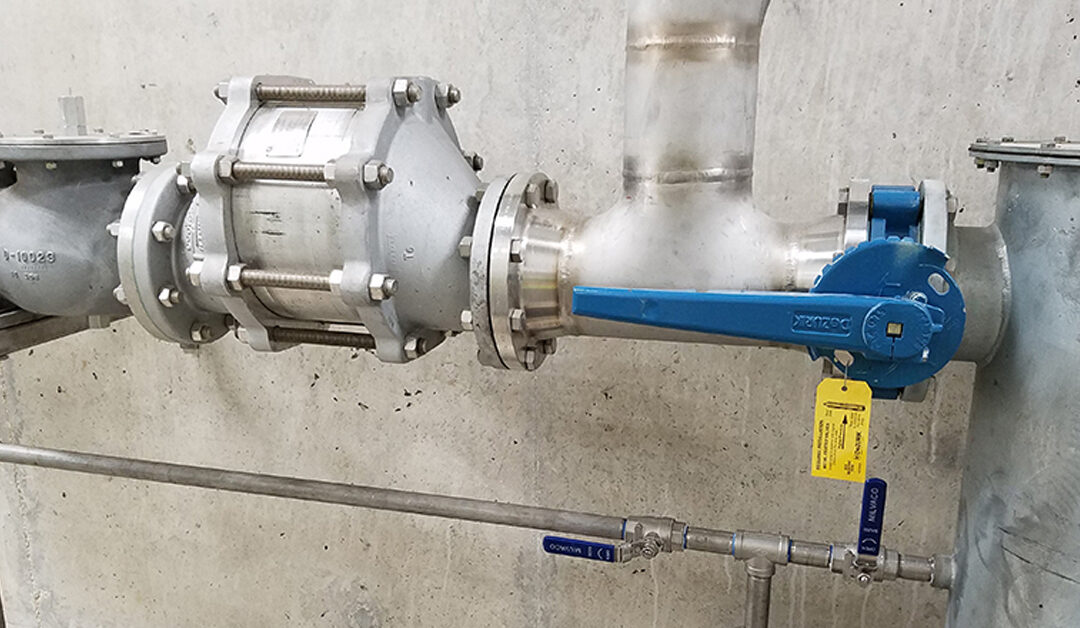

Medford wanted to replace their existing DAF (dissolved air flotation) thickener with improved performance and reliability. They also wanted to reduce recycle flows and install a new plant washwater system. The new thickening system needed to have a small footprint to fit into an existing, unused building. Ben Brooks from the City of Medford consulted with Eric Lynne from Donohue & Associates, Inc. in the design of the new thickening system.

Medford Existing WWTP

- 0.6 mgd avg

- 1500 lb/d BOD avg

- Activated sludge WWTP • Influent fine screening

- Grit removal

- A/O Activated sludge with final clarifier(s) • RM/Coag/Floc + cloth disc filtration

- UV disinfection

- DAF

- Aerobic digestion

- BFP

- Seasonal land application

Is DAF a typical system for sludge thickening in Wisconsin?

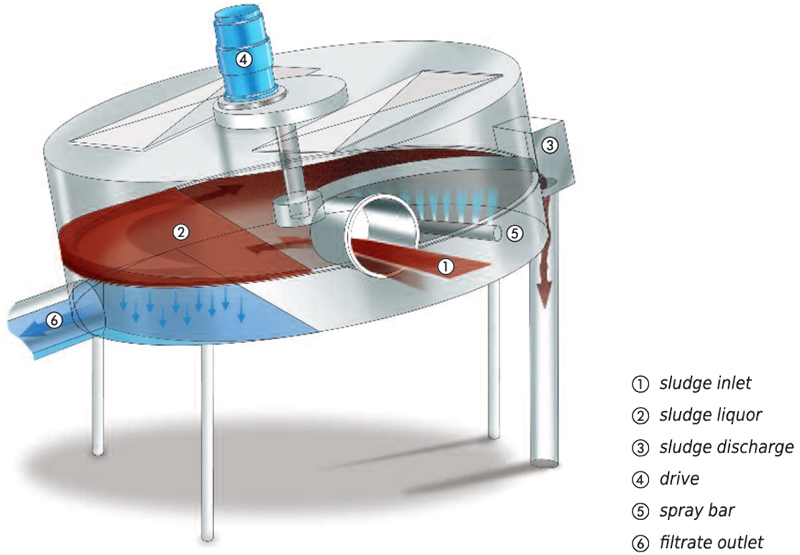

DAF thickening has a handful of installations around the state. Nowadays people are looking at more up to date technologies for sludge thickening, which includes the disc thickener that HUBER provides.

Why was the S-Disc sludge thickener selected for Medford?

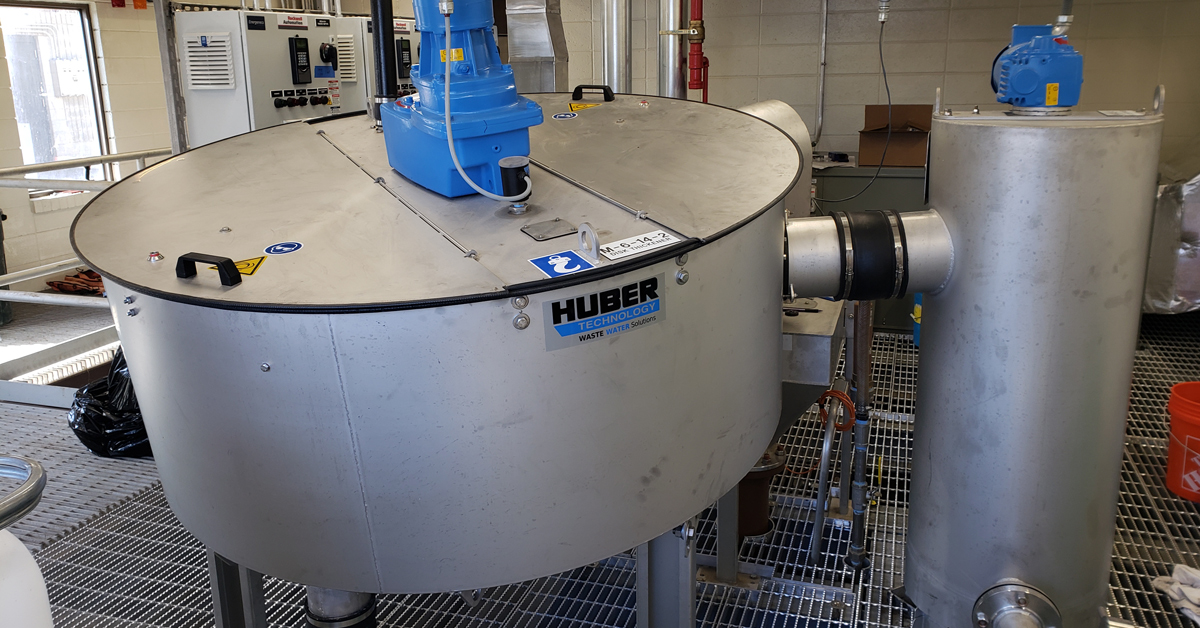

The reason they chose the HUBER unit was because of its small footprint. They wanted to fit it into an existing building, so the smaller the footprint, the better. Also, ease of operations. This is a very simple system, it can run independently and it’s self-cleaning, which is good for maintenance.

It was sized appropriately to treat the amount of sludge that the plant generates every day. They take the sludge from the clarifier and then they thicken it with the HUBER S-disc thickener. After thickening, it goes to their aerobic digesters. Thickening certainly reduces the volume of water you are hauling off-site which can save the City money.

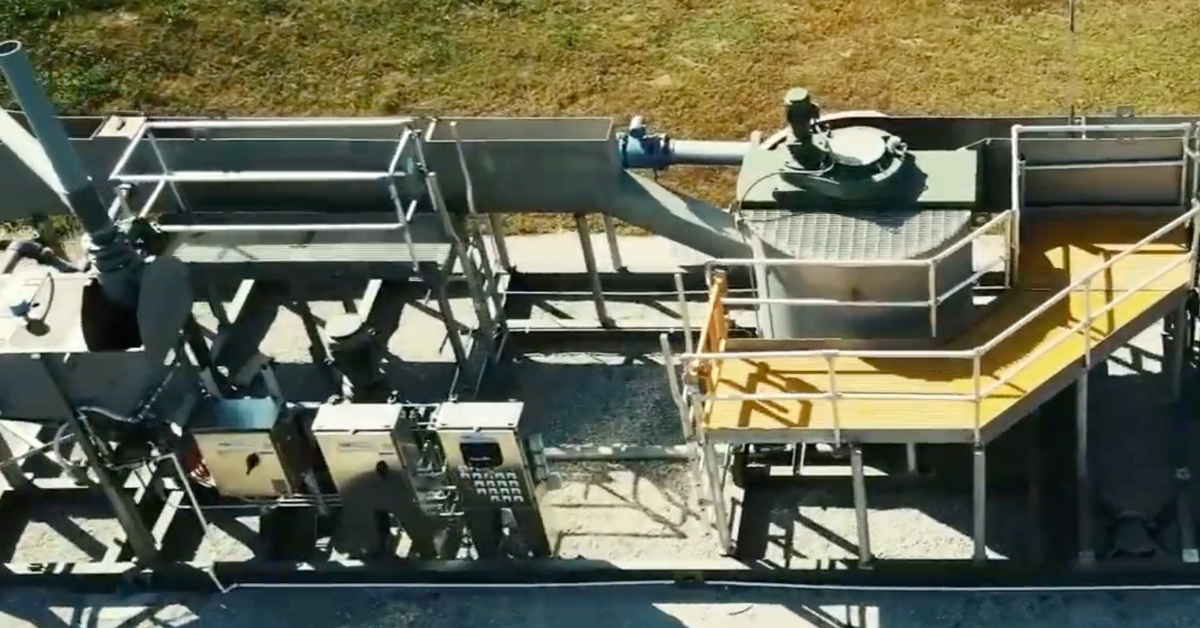

S-Disc in action, top view

S-Disc in action, discharge view

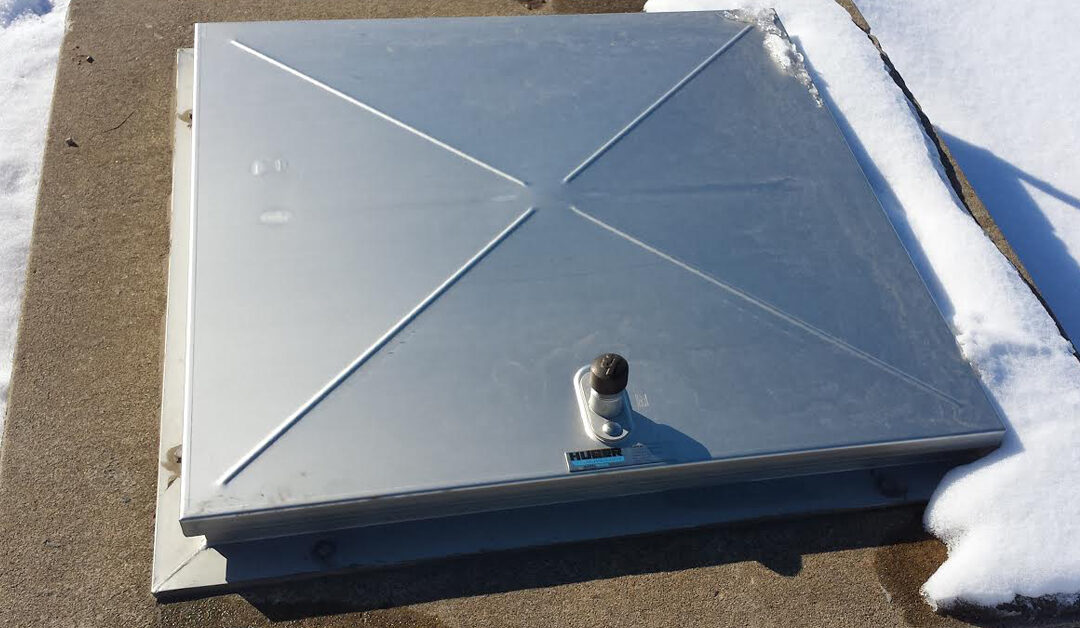

HUBER S-Disc in City of Medford, Wisconsin

HUBER S-Disc with Control Panel on back wall

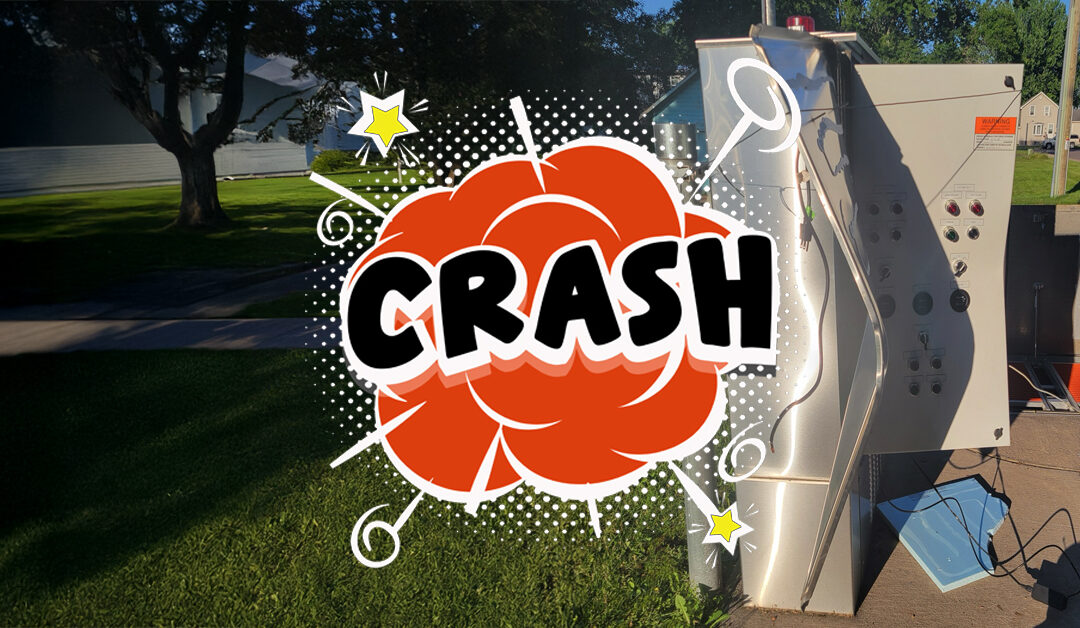

Energenecs added the S-Disc to Medford’s SCADA network

Energenecs coordinated with Donohue and Medford when the S-Disc was designed to go into that building. There is a control panel and variable frequency drives, plus instrumentation that all gets wired and connected on their fiber optic ethernet network. Tom Robarge, SCADA technician at Energenecs programmed the Allen Bradley system to connect the HUBER S-Disc controls to the Medford SCADA network, which allows operations personnel to monitor and make adjustments to the thickening process. So from the control room they see the S-Disc, they can monitor it and make polymer and other adjustments.

Is there a plant size that is ideal for the S-Disc?

The HUBER S-Disc sludge thickener is economical for a wide range of plant sizes, from 100,000 gpd to a really large plant like the one in Springfield, Illinois which is using four HUBER S-Disc sludge thickeners between two plants. There are two HUBER S-Disc sizes available; Size 1 and Size 2. Most of our applications are Size 1.

What other sludge thickeners are typically used?

HUBER has a rotary drum thickener which is for larger applications, but for the bulk of the size of our plants in the state, the S-Disc thickener seems to be a very good fit.

What about capital costs?

The HUBER S-Disc is self contained which makes it very easy for a contractor to install. So the overall economics are very cost competitive. The S-Disc sludge thickener is tank mounted and includes an integral drain. You can see at Medford it’s not even sitting on concrete, it’s sitting on floor grating. The drain goes to wherever the plant wants to send it. With a gravity belt thickener, they allow that water to drain right on the floor which means you have to build a curb underneath the belt to collect the water. It’s costly to construct additional concrete work.

What about the consumables?

It is a more efficient system, so it probably uses less polymer than they did before. Initially they will try different polymers through jar testing and then they will focus on what is most effective.

What about odor?

It’s a covered tank so it keeps odors under control. The DAFT unit is typically open on the top and operators comment that odors are minimized with this S-Disc system.

How long does it take to install?

Mechanically, it’s only a day or two, since it’s pre-assembled in the factory and ready to go. The equipment comes out with legs that you bolt to the floor. With plumbing and electrical hook-ups, total installation time is probably two weeks, but that all depends on the site constraints.

How long has HUBER been in business?

In general when clients consider different manufacturers they want to know how long companies have been in business. HUBER is a family owned company that has been around for over 150 years. They are highly successful and respected.

Is an S-Disc pilot unit available?

If people are interested in the technology and the pilot unit is available, HUBER will go to the job site and thicken their waste sludge with an actual full scale trailer-mounted S-Disc pilot. This will give them a very good comfort level because they see the performance, how it operates and how easy it is to maintain. Read about the Sister Bay pilot study at energenecs.com/discthickener

Other HUBER S-Disc Sludge Thickener Installations in Illinois and Wisconsin

Previously, we were really limited in how we could show off the technology. Now that we have four local installations, we now have places where people can go, plus people can talk to other operators and see them at trade shows. Plant operators like to talk to other plant operators to see and touch the equipment that they could potentially buy. In the case of Medford, the pilot unit was not available so the next best thing was to go visit a nearby site in Springfield, Illinois. Eric Lynne from Dohonue, City of Medford representatives, Huber personnel and I went down to Springfield Illinois to see their HUBER S-Disc sludge thickeners. They got to talk to the operator and ask all the questions that they had about their experience with it and came back very comfortable with the technology.

Springfield, Illinois

Springfield currently has four S-Disc units in operation. The Spring Creek Wastewater Treatment Plant has a design flow of 32 mgd, the biological nutrient removal plant is one of the largest in Illinois.

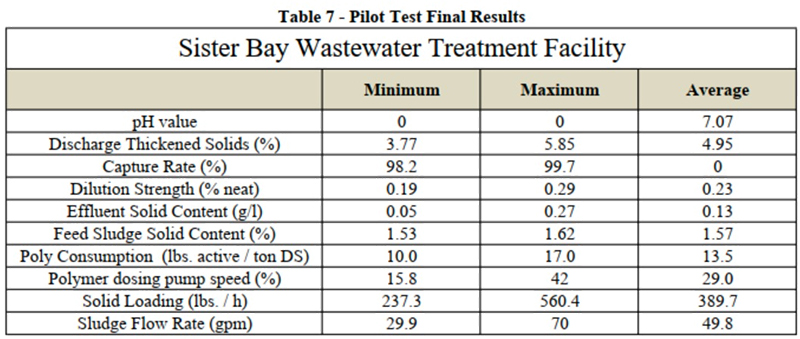

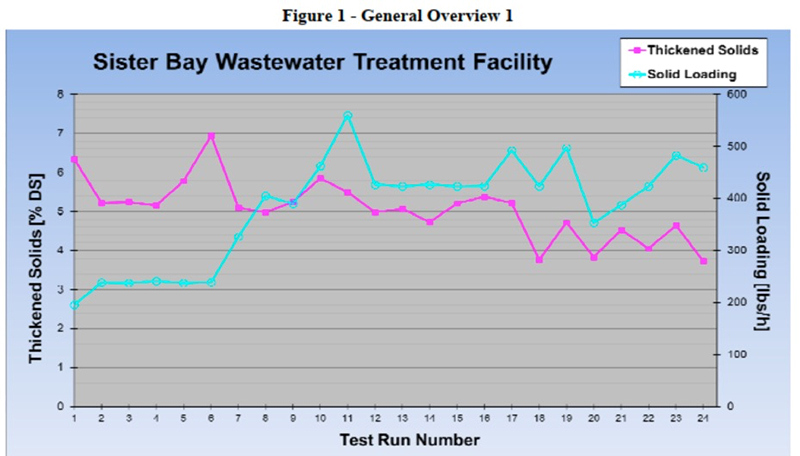

Sister Bay, Wisconsin

Sister Bay did a pilot study (see results)* in 2019 and they liked what they saw, so they bought their own HUBER S-Disc unit, which is currently in operation. Read about the pilot study at energenecs.com/discthickener

Cheese Plant, Wisconsin

The S-Disc sludge thickener has also recently started up at a cheese plant in southeastern Wisconsin. The HUBER disc thickener system will normally thicken 100% Waste activated sludge (WAS) from approx 0.5% up to 4 to 5% Total Solids, and has the capability to thicken solids to over 6%. This reduces the storage requirements substantially.

Village of Twin Lakes, Wisconsin

Energenecs has also sold an S-Disc unit for the Village of Twin Lakes, which is a 750,000 gpd wastewater treatment plant located in the southeast corner of Wisconsin. We are in the production process right now and it will be running in early 2022

*Sister Bay HUBER S-Disc Pilot Study Results

More Info about the HUBER S-Disc Sludge Thickener

For more information about the HUBER S-Disc sludge thickener installations in Wisconsin, contact Steve Berggruen at 262-377-6360.

0 Comments