Meet Team Member Nate Wolfe

How did you get into this industry?

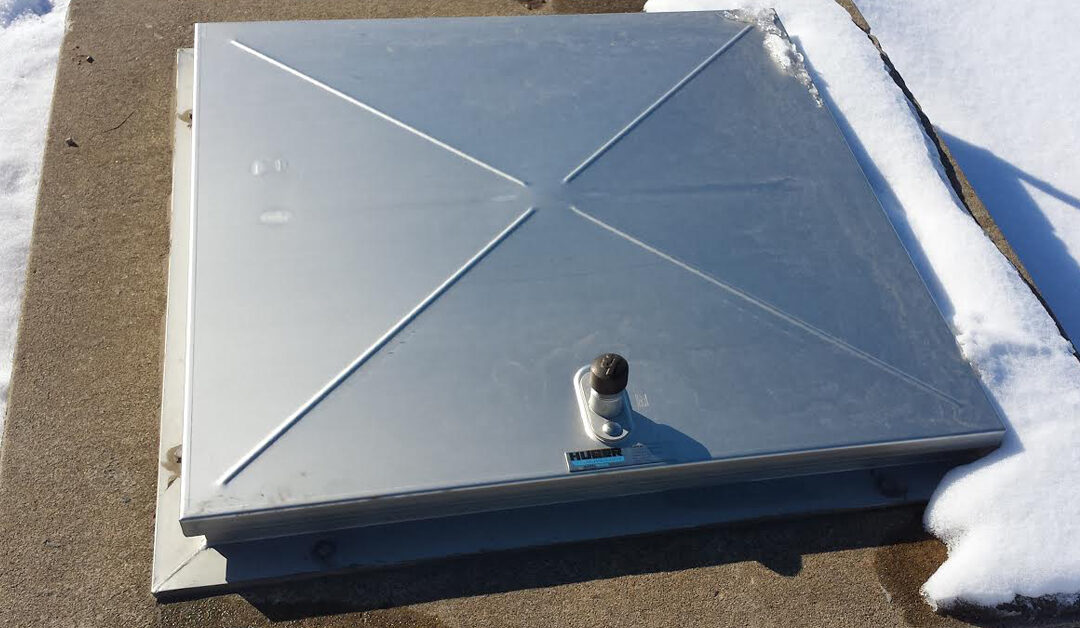

My uncle! (see photo) All through high school and college during the summers I would work in the family business as an electrician. I have a mechanical engineering degree from UW-Madison, and after college I was still working as an electrician. My uncle worked for a small company, Kamp Synergy, and he thought with my engineering and electrical background it would be a good fit for me. I took a look at what he did, was interested, and got a job with them in 2003. It was fantastic working with such a good group of guys! I worked with them until the owners retired and sold the company to Energenecs in 2013. The whole company came over to join the Energenecs team. Out of that original Kamp group I am still working with Bill O’Neal (field service technician). Bill and I have been working together almost twenty years!

Can you explain a typical water control project?

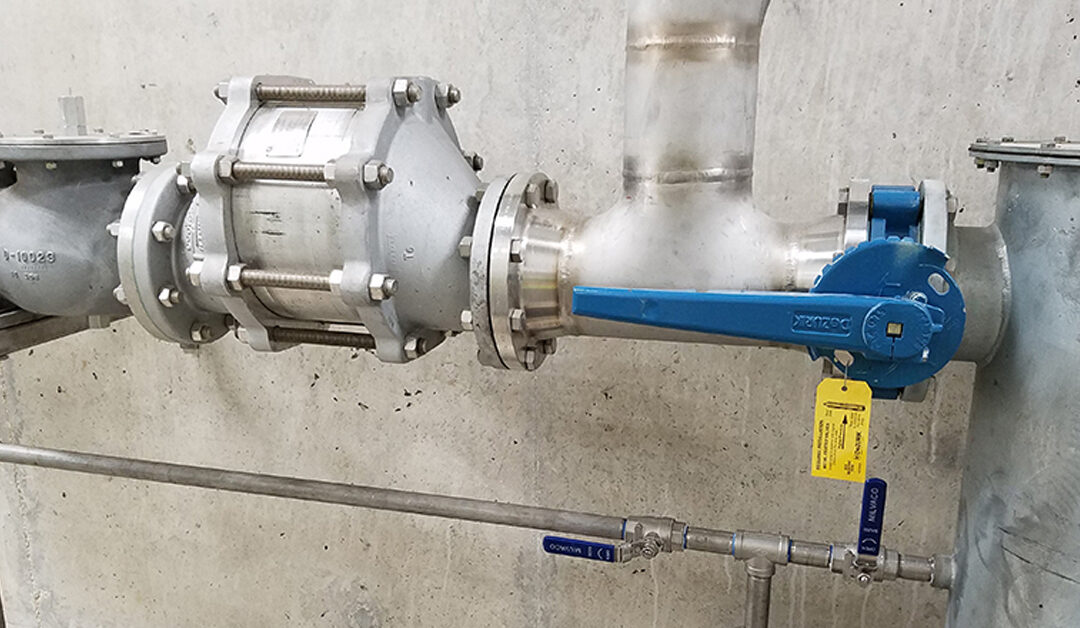

I’ll walk you through a water tower project first. With water systems around here, we measure the amount of water in a water tower. When it gets low, we turn the wells on around town to pump water into the system. As water is pumped into the system, the water tower level rises. When it’s full, we turn the wells off. The controls are completely automated and the operators are able to adjust the control and alarm setpoints to get the system to behave correctly for the needs of their unique application/city.

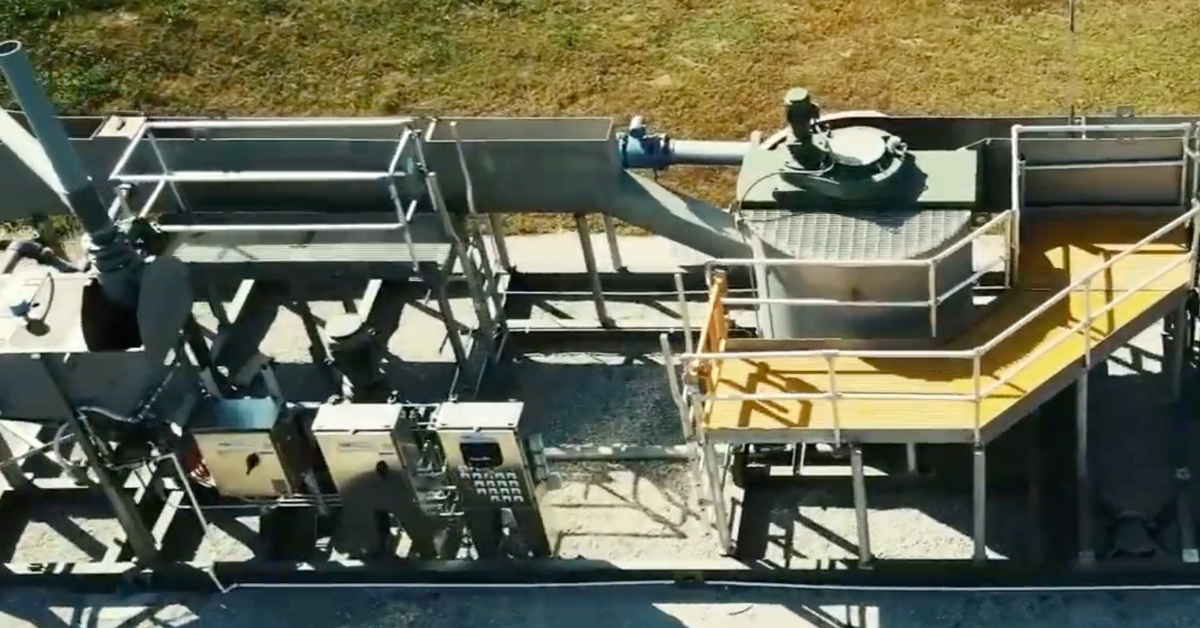

A wastewater system is everybody’s sewage and sometimes rainwater. When people use their showers, sinks and toilets it flows in pipes downhill and collects in low spots where towns have lift stations. A lift station is just a big vertical pipe where all the sewage collects and then pumps run to pump the sewage out higher so it can run to the next low spot, then eventually to the wastewater treatment plant. The pumps in the lift stations are controlled by the sewage level at the site. Once at the wastewater treatment plant the sewage undergoes several steps of filtering and treatment to clean it up, and clean water comes out the other side!

The actual controls for these systems are usually not very complex. What is tricky is handling and presenting the large amount of information generated in a way that is organized, intuitive, and not overwhelming. Getting all of the different pieces of a system to come together in one cohesive unit is an ever-changing challenge.

What is your process for designing a control system?

Once the technical sales person and project manager settle on an initial design, I will get a list of things that need to be monitored by and controlled by our system. From there I draw out a line diagram of devices being controlled and points being monitored. I may go back to the customer or project manager if I need clarity on how any particular device is supposed to be controlled. After I have a decent idea of what is included in the system I start making a large list of data points that will be included in the system. This list helps me keep track of the data when making the PLC programs, communication paths, touchscreens, computer screens, alarm callouts, and reports. After the planning is done, I get to do the fun part and create!

I’m working on a water well station right now. By looking at the list of devices in front of me on my computer screen, I am able to do a number of things. I can turn a well on and off, turn chemicals like chlorine, fluoride, and phosphate on and off, and determine the speed at which they are running. I also get a pressure signal, flow rate, residual (how much chemical is in the water) and temperature. The first thing I do is gather all the signals that are coming in to me, then figure the totals, highs, lows, averages, and alarm setpoints.

The signals come in through a PLC (programmable logic controller), which is like a small robust computer. This computer has a bunch of screws you put wires under, and they give me either an on or off (digital) signal, or a signal where I measure the current (4-20mA) going through the wire (analog).

I make sense of all those signals using a big spreadsheet of what everything needs, where all my data is, and then I’ll make a touch screen out at the site which shows you what’s going on as far as measured values and what’s happening. There are also buttons and setpoints for when to turn things on and off, or when to make high and low alarms.

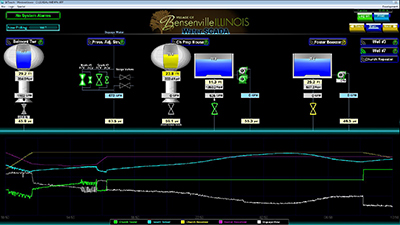

We usually put in radios with antennas that are able to talk to each other, so sites all over the city can report back to an actual computer. On that computer I make informative graphics so the operator can see what’s going on at a glance, change the setpoints, plus view graphs, reports and alarms.

Every city, town and village is unique. They will have different sensors and inputs and different ways that they want their system to operate. There are thousands of inputs, so a big part of what I do is organizing it, so it is usable and not overwhelming.. My basic building blocks that I use to take a signal in and create alarms and totals have been refined by years of servicing systems and are pretty much the same between cities.

How do you maintain or troubleshoot systems?

Energenecs field service technicians are great! They travel all over the place. They can plug in their laptop, and I can work on stuff remotely while they do physical things on site. Our field technicians and I communicate and work together very well.

With computer remote control being possible now, I can be on multiple computer systems (too many!) during the span of a day. I will also help customers diagnose issues themselves. Pictures really are worth a thousand words in those instances!

What is a common question you get?

Do you have time for a quick question? [laughs]

What do you like best about being a SCADA tech?

0 Comments