Illinois WWTP see 70% Energy Savings with New Aerobic Digestion Process

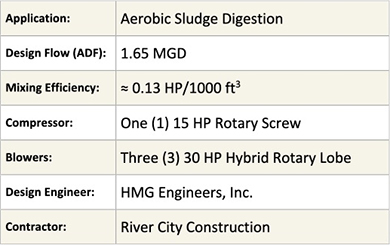

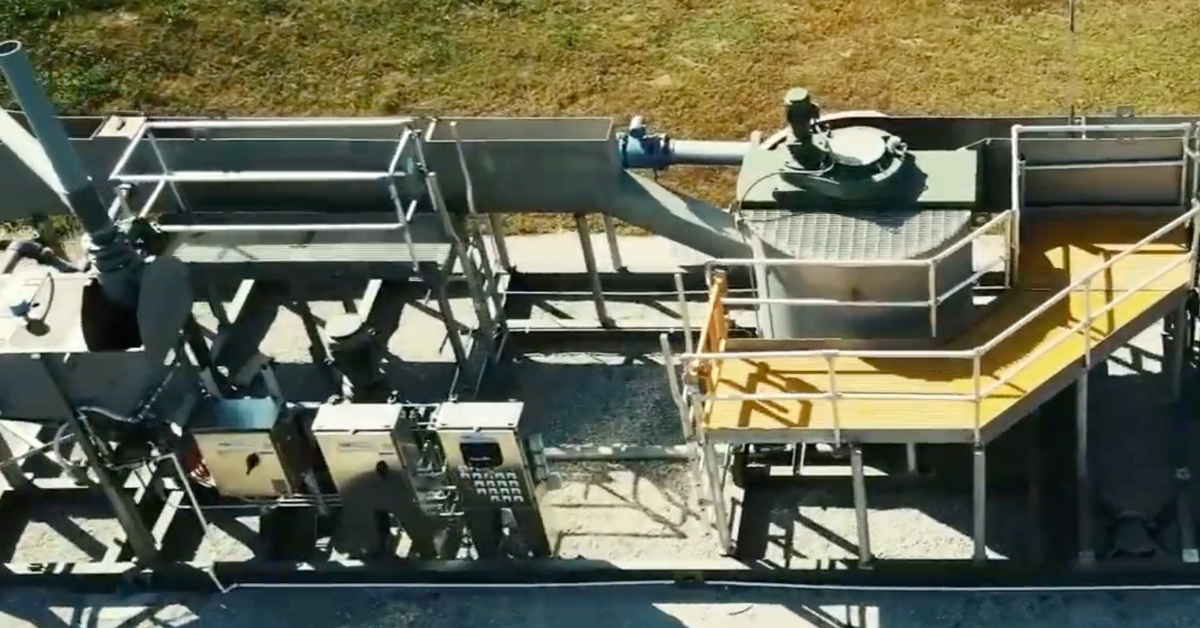

In 2018, the City of Benton, Illinois, constructed a new wastewater treatment facility to replace the antiquated decades-old plant and to provide improved treatment that meets nutrient removal requirements. The new facility was designed to treat 1.65 million gallons of wastewater per day using an oxidation ditch, which facilitates nitrification and biological phosphorus removal.

EnviroMix’s BioCycle-D optimized new aerobic digestion process was selected as an integral part of the new plant design because of the significant energy savings and improved sludge digestion through automated process control that the system provides.

Optimized process conditions

Unlike a conventional aerobic digester that uses diffused aeration for both mixing and process oxygen demands — resulting in over-aeration which leads to uncontrolled nitrification, depletion of alkalinity, and increased energy consumption — BioCycle-D controls and optimizes the digestion process.

Aeration & mixing system designed solely based on requirements

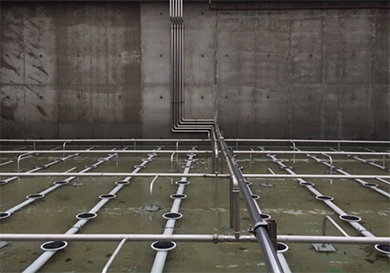

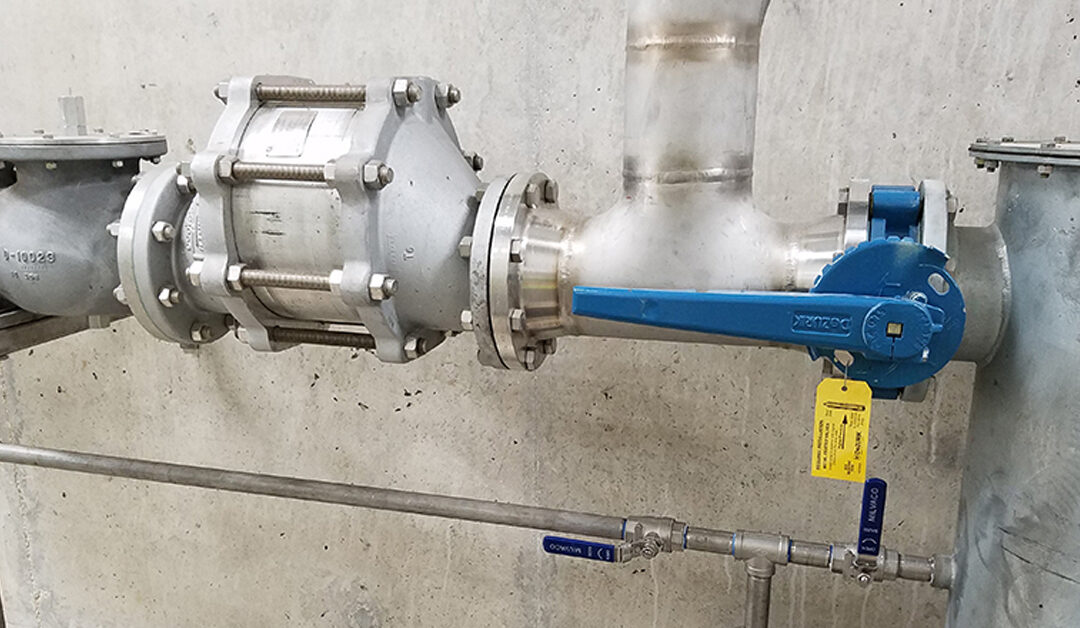

BioCycle-D is designed by right-sizing the diffused aeration system to satisfy process oxygen demand and applying energy efficient mixing through the use of the BioMixTM Compressed Gas Mixing System.

The conventional approach to aerobic digestion design utilizes the aeration system to provide the oxygen to the microorganisms as needed for the digestion process AND the mixing energy needed to keep the basin contents mixed at all times. Oftentimes, and especially for treatment works that have extended aeration secondary processes, the air required to mix is greater than the air required to satisfy the oxygen demand, resulting in wasted energy. When the aeration system is designed solely based on the oxygen requirements and the mixing system is designed solely based on the mixing requirements, efficiency and operational flexibility are both maximized.

BioCycle-D maximizes sludge destruction, minimizes energy consumption, and provides process control by decoupling aeration from mixing along with automated operation through instrumentation feedback.

Instrumentation feedback and monitoring

Energy savings and improved sludge digestion

The Benton wastewater treatment facility is experiencing over 70% energy savings versus a conventional diffused air mixing system designed at the Ten State Standards volumetric airflow rate of 30 scfm per 1000 ft3 of tank volume.

In summary EnviroMix’s Compressed Gas Mixing System enables solutions that reduce energy consumption, simplify maintenance, and optimize process conditions, enabling highly scalable and flexible operations.

0 Comments