Energenecs provides Innovative MBBR for Nitrogen Removal

Energenecs recently provided an MBBR for nitrogen removal to a small town (100,000 gpd) in Northern Wisconsin with a focus on minimizing energy & chemical consumption. Innovation technologies, plus extensive controls and sensors were also added to further increase efficiency for a client that values sustainability.

What is MBBR?

MBBR is a mechanical wastewater treatment process that was invented in the late 1980s in Norway. There are currently over 700 municipal and industrial MBBR wastewater treatment systems installed in over 50 countries.

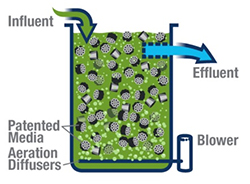

An MBBR (Moving Bed Biofilm Reactor) system consists of an aeration tank (a swimming pool sized concrete basin), similar to an activated sludge tank, full of small plastic carriers, which are the size of a quarter. The carriers provide a surface where a biofilm can grow and are mixed in the tank by the aeration system, providing good contact between the substrate in the influent wastewater and the biomass on the carriers.

Flow enters the fully-aerated tank and encounters the biofilm-coated media. Coarse effluent screens prevent the plastic carrier media from leaving the aeration tank.

What is the difference between activated sludge and MBBR?

The conventional way to treat wastewater is activated sludge where you have a suspended biomass floating around in the wastewater and you let that settle out in the clarifier, then pump it back into the main aeration basin. MBBR technology uses plastic media to house the bacteria, so you don’t have to settle, capture and return it. It just stays in the basin, so it tends to be a more robust, resilient process and is less prone to upsets that could cause settling issues.

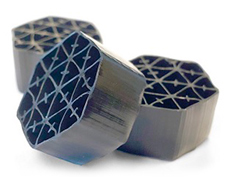

BioPorts plastic carrier media provide high biologically active surface area for increased biomass growth.

What are the benefits of MBBR?

The footprint of the MBBR system is quite a bit smaller than what you would need for activated sludge. MBBR can also be less expensive and less difficult to operate than activated sludge systems.

The other benefit of MBBR’s plastic carriers is they grow bacteria that remove ammonia (nitrifying bacteria). Nitrifiers are super slow growing and could be difficult to grow in activated sludge because you would need a large biomass and large volume of aeration basins. It’s also difficult to grow nitrifiers in cold water with an activated sludge process. Winters are very cold in northern Wisconsin, so these biofilm media carriers are a really nice solution.

Other MBBR Advantages

- MBBR systems don’t need recycling of the sludge

- An existing treatment plant can increase its capacity by simply retrofitting existing basins and adding plastic media (this is called IFAS – Integrated fixed-film activated sludge). This will typically increase treatment capacity more than two-fold and enable ammonia removal.

- Higher effective sludge retention time (SRT), which is favorable for nitrification

- Responds to load fluctuations without operator intervention

- Lower sludge production

- Resilient to toxic shock

- Doesn’t rely on settling. Process performance independent of secondary clarifier due to the fact that there is no sludge return line

Energenecs provides MBBR System in Northern Wisconsin

Why was the town seeking a new wastewater treatment system?

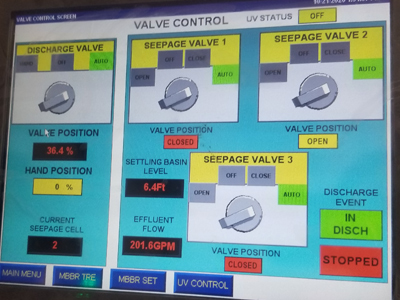

The town is located in northern Wisconsin with a population of about 3,000. They process about 100,000 gpm (gallons per day) of wastewater and have been talking about a new system for several years. They had a lagoon system and seepage cells, so the water goes through the lagoon system, where it would stay for a couple of months and was treated naturally with algae and other processes. No mechanical activity at all. Then the treated water would go into the seepage cells where it would flow into the groundwater. The whole wastewater treatment system was built in the 1960’s and the seepage cells were no longer functioning. For the past several years they have been discharging to a wetland nearby. The discharged water was eventually flowing into pristine lakes, which were having problems with harmful algal blooms.

What other wastewater treatment systems were they considering?

Initially they looked at a floating aerator system. They tested surface aerators in the lagoon to see if that would fix the problem, which it didn’t. They procured an engineering report where they looked at different options for addressing the problem and settled on the MBBR system to take the water from the lagoon and post treat it, plus construct new seepage cells, to discharge into the groundwater again.

MBBR for nitrogen removal

This client was looking at primarily nitrogen removal and MBBR’s are well-suited for that because they accommodate slow growing nitrifiers well and can be easily configured to have different zones which are required to convert ammonia to nitrate then to nitrogen gas.

System focuses on minimizing energy and chemical consumption

The town especially cared about energy and chemical consumption and wanted to minimize those things as much as possible. They are very environmentally conscious and focused on sustainability, so Trevor Ghylin of Energenecs spent time putting together an innovative proposal to address their concerns. The system is currently using less than 5hp on average, whereas competing proposals with traditional MBBR designs required 40hp, nearly 10 times more energy consumption. Trevor was really focused on innovative designs to make sure they are not using any more energy or chemicals than is absolutely needed.

Fine Bubble Aeration and Big Bubble Mixing

Typically MBBR systems use coarse bubble diffusers which provide both aeration and mixing, but they are not very efficient at either one of those things.

Fine bubble aeration was proposed for this site instead of coarse bubble due to the small basin size and ease of retrieving diffusers mounted on single drop air pipes. Fine bubble diffusers are twice as efficient as coarse bubble diffusers, which are typically used.

The proposed mixing system utilized innovative new technology in the form of a large bubble mixing system. The large bubble mixing system is the lowest energy solution and is very well-suited to this application as there are 4 separate zones that require mixing. Using a traditional submersible mixer would have required at least 4 mixers with 4 separate motors, resulting in high energy consumption and high maintenance. The large bubble mixing system consumes very little energy comparatively and is powered by a blower in the climate controlled control room.

Aeration savings

- Fine bubble diffusers save 50% compared to coarse bubble

- Ammonia-based aeration control saves an additional 25%

- NH4 setpoint = 5 mg/L instead of 0 mg/L

- Nitrate recycle saves an additional 25%

Chemical Savings

- Ammonia-based aeration control minimizes alkalinity consumption by treating only as much ammonia as necessary. This also reduces aeration energy consumption and reduces nitrate production thereby reducing glycerine consumption for denitrification.

- NH4 setpoint = 5 mg/L instead of 0 mg/L

- Nitrate recycle recovers alkalinity used by nitrification and further reduces chemical demand

- Chemical feed control minimizes chemical dose for glycerine and alkalinity

Energy Efficient Bubble Mixing by EnviroMix

Energenecs’ partner, EnviroMix provides innovative technologies which harness the power of large bubbles for highly energy efficient complete mixing. Using short, powerful bursts of compressed gas through engineered nozzles affixed to the floor of the channel, tank, digester, or reactor, these large bubbles lift and roll fluids, blending the contents. By decoupling aeration from mixing, both can be much more efficient.

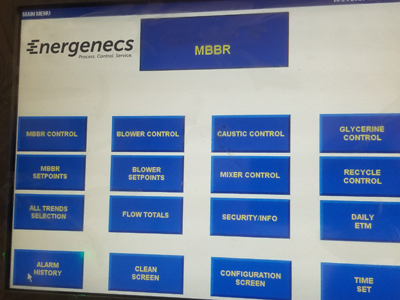

Control systems and sensors improve efficiency

Energenecs also put in control systems and sensors to measure ammonia, nitrate, oxygen, alkalinity, pH and temperature. All the important measurements so they can aerate only as much as needed and also control the glycerine and caustic dosing. This is a modern, smart treatment system that uses real-time process data and automation to ensure treatment objectives are met and energy and chemicals are not wasted.

Ammonia-based aeration control (ABAC)

- Includes DO Control

- Simple operator input: NH4 & DO setpoint

Glycerin feed control

- Online nitrate measurement

- Simple operator input: NO3 setpoint

Caustic feed control

- Online alkalinity measurement

- Simple operator input: alkalinity setpoint

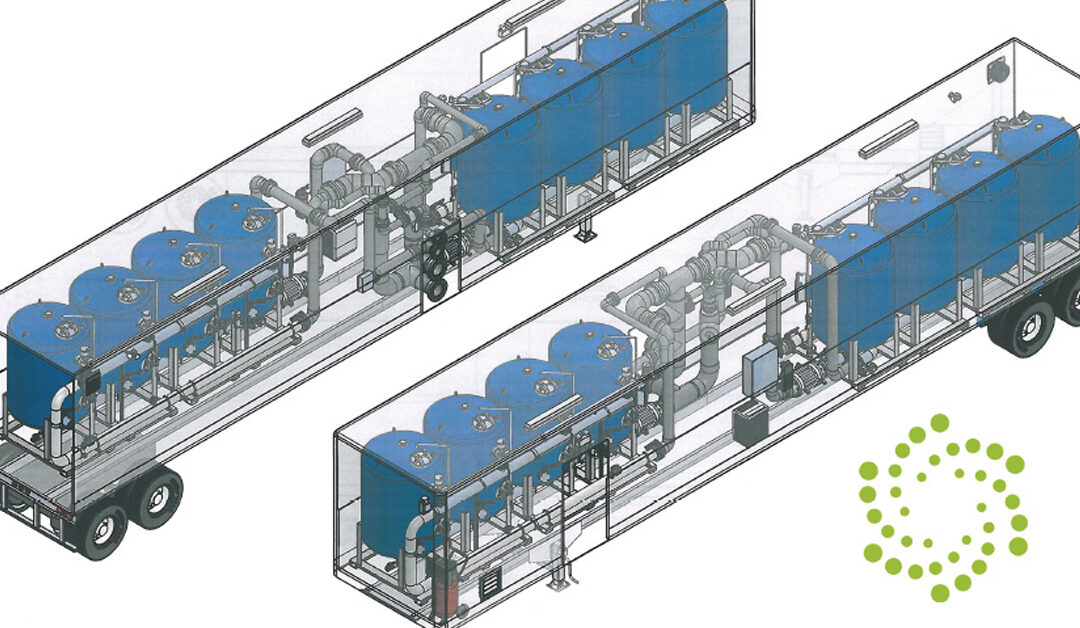

When did the MBBR installation start?

This project has been under construction since December 2019. Energenecs supplied the equipment, SCADA (supervisory control and data acquisition) and remote communication. This was a huge team effort by Energenecs headed by Trevor Ghylin, Steve Berggruen and Brian Akason. Alex Muench was project manager. Craig Sampo, along with Kendall Kildow were up there starting up the mechanical systems including the chemical feed systems, submersible pump, and the sensors. Rick Bartelt has been doing the programming. The MBBR was built next to the lagoon and the three ponds are still there. They are keeping them, and will continue to use them. They do the bulk of the treatment, as the water sits in there a long time and a lot of the stuff settles out. There is algae that grows and treats the water naturally. Then it comes out the back end and the only thing left in it is some organic matter and ammonia nitrogen. The purpose of the MBBR is to remove the ammonia/nitrogen prior to groundwater discharge.

What is the process for this MBBR system?

MBBR has two steps: it removes the ammonia with slow growing bacteria that work well in the plastic media carriers. The bacteria convert the ammonia to nitrate in an aerobic zone then the water moves to an anoxic zone where glycerine is added for bacteria to convert the nitrate to nitrogen gas that bubbles out of the water. The system has an alkalinity dosing system that adjusts the pH and alkalinity if the nitrifying bacteria are alkalinity-limited. Also, a glycerine feed system that is needed for nitrate conversion. You have to feed organic carbon of some sort to the bacteria that remove the nitrate. The client chose glycerin because they have a cheap source for that.

MBBR from the operator’s point of view

MBBR is simpler than an activated sludge system. Kind of set it and forget for the most part. The bacteria grow on the plastic media and just stay there. Whereas with the activated sludge system you are counting on settling and returning the sludge to the aeration basin. You also have to monitor the biomass and control your wasting rate. You can get problems with filaments where they don’t settle out well. Activated sludge is definitely more of a hassle because you have to watch it more closely.

Remote communication with the system

The client has a remote alarming system, and Energenecs added remote communication with the site so they can log in and monitor the process. They can change settings and operate it remotely. Trevor knew this was going to be a unique project and he wanted to make sure he could support the system without having to be onsite. Energenecs is going to make some programming changes as they go, and their programmer can just log on and do that remotely as well.

Nexom’s BioPorts MBBR Solution

Energenecs’ manufacturing partner, Nexom offers a MBBR solution, BioPorts. BioPorts technology works very well as a stand-alone MBBR process or as part of a larger process, such as an integrated fixed-film activated sludge (IFAS) process. Its patented media optimizes surface area for attached growth. In addition, the carriers’ dimensions are engineered to carefully balance size and shape to enable both coarse media retention screening and effective media motion. BioPorts also offers Screen Scour, which disperses media collecting on effluent screens, a particularly indispensable function in anoxic denitrification basins.

0 Comments