Control Upgrade Saves Energy without Re-tuning

Smart Control Upgrade to Minimize Energy Usage

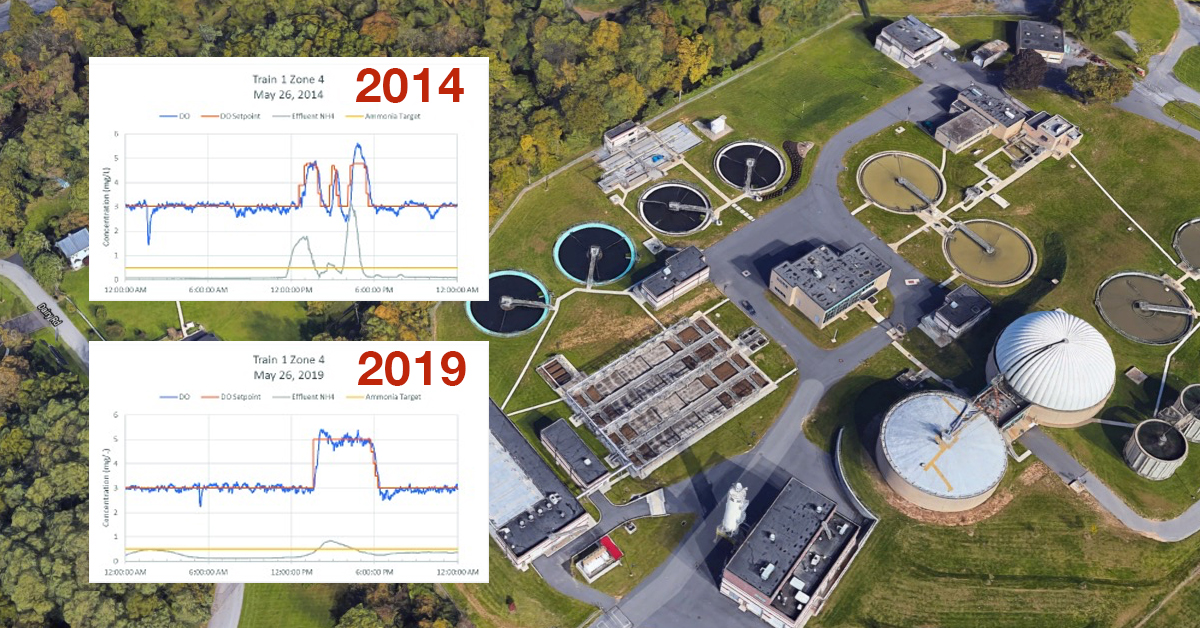

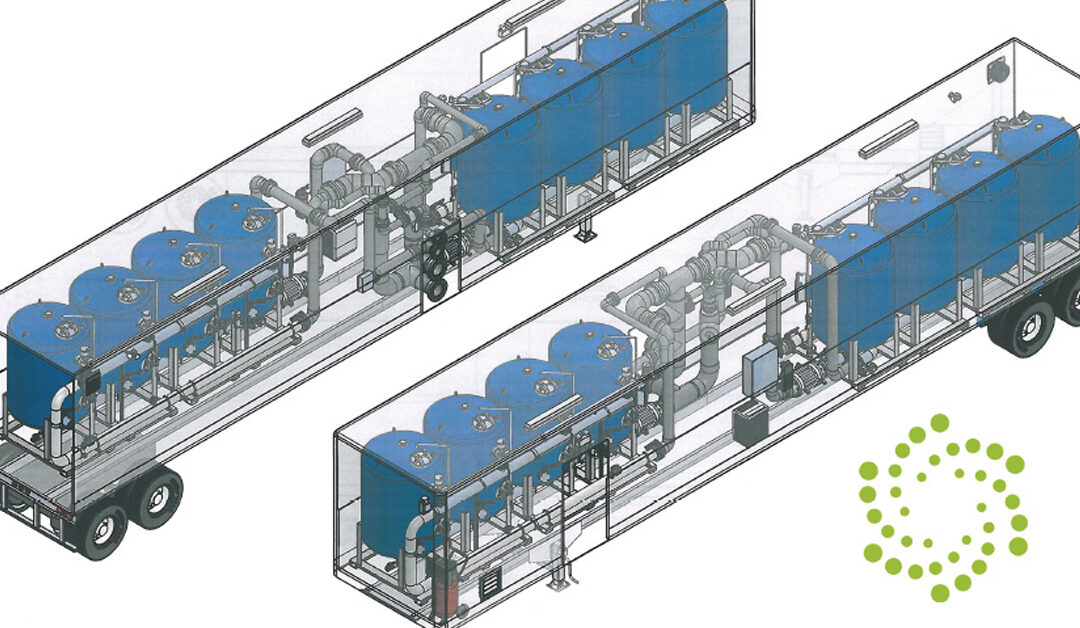

In 2012 the City of Lebanon Authority Wastewater Treatment Plant was upgraded with a smart digital control solution to support its complex operations, minimize energy usage, and comply with new effluent total nitrogen limits. The control system is a featured technology of Environmental Dynamics International, Inc.’s (EDI) Symphony® Operating Management System.

Optimization Controller Continuously Calibrates in Real-time

In consultation with BioChem Technology (the digital technology provider in the Symphony Operating Management system), a process optimization controller that manages a bypass loop around the trickling filter and the operating parameters for the IFAS process at the plant was provided. This ensures that the two process units are operated in concert for best combined performance, and energy and chemical efficiency. The controller uses a model-based algorithm that is continuously calibrated in real-time. The controller now recognizes and accounts for changes in performance as the configuration of the system and process set points are optimized in real-time.

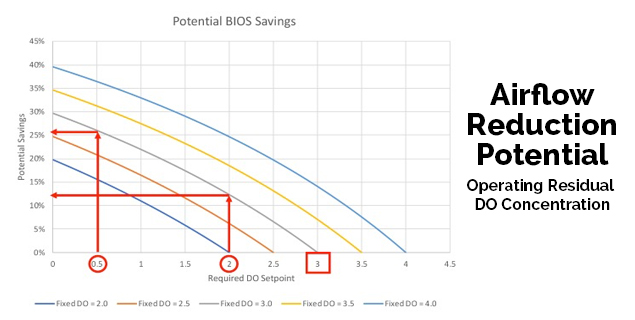

Process Optimization System Reduces Energy Usage 15-25%

A complementary aeration control system automates the operations of the diffusers and blower components. A combination of model-based algorithms is used to determine airflow and valving requirements. The algorithms account for oxygen transfer and pressure differences with fine- and coarse-bubble diffusers and uses dynamic most open valve optimization to minimize the operating pressure at the blowers. The solution also uses machine learning to provide tight automation performance as loading, temperature and diffuser operating performance varies. The control system enables the plant to meet permit requirements while minimizing operating cost. The process optimization system is reducing energy use by an estimated 15% compared to operation with fixed DO set points. Further, the aeration control system is delivering an additional 10% reduction in energy compared to traditional PID-based control.

Still Performing without Re-tuning Since 2012!

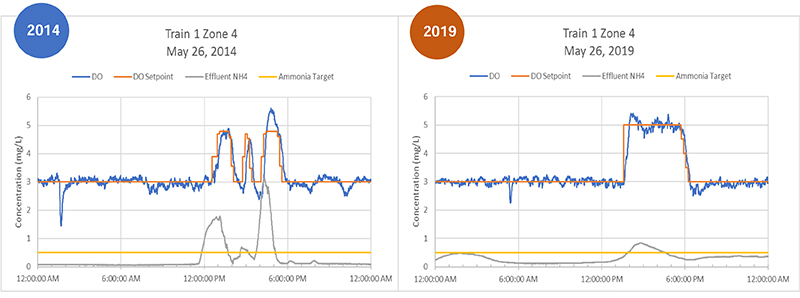

The control solution has performed without additional tuning since commissioning. System performance was documented two years after commissioning in 2014 and again in 2019, after seven years. When within the operating range of the associated components (blowers and valves), the aeration control system maintains a residual (DO) within ±0.5 mg/L of the set point more that 95% of the time. The process optimization system also continues to adjust critical setpoints to provide desired treatment performance.

This level of automation performance is unique considering a recent ABB study stating that control systems have a half-life of six months and must be re-tuned regularly to maintain system performance. That report also says 75% of control systems are not adding value (30% increasing variation, 15% out of range, and 30% in manual operation). The steady performance of the City of Lebanon Authority control system (more than seven years without manual re-tuning) is setting a new standard for the industry.

0 Comments