Keeping Costs Down with a Turnkey Lift Station System

We spoke to Alex Muench, project manager at Energenecs, about one of his recent projects, a turnkey Integral Valve Vault Submersible Lift Station system for a developer in Eau Claire, Wisconsin. Alex provides coordination between manufacturers, contractors and consulting engineers, along with the Energenecs’ control team. He reviews plans and specs, coordinates approvals, and orders equipment. Alex also tracks the project schedule and manages the lift station project until completion.

What was involved in this lift station system?

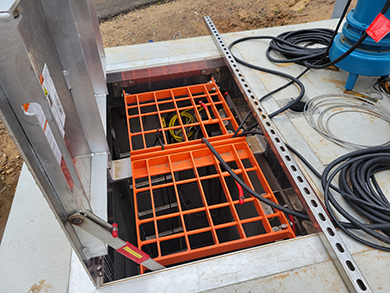

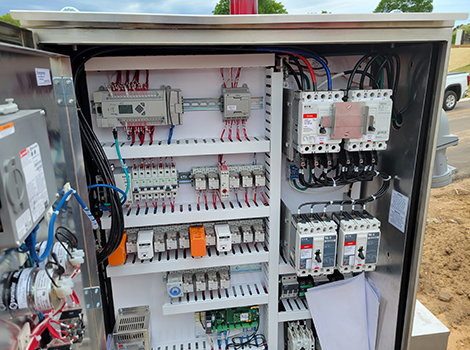

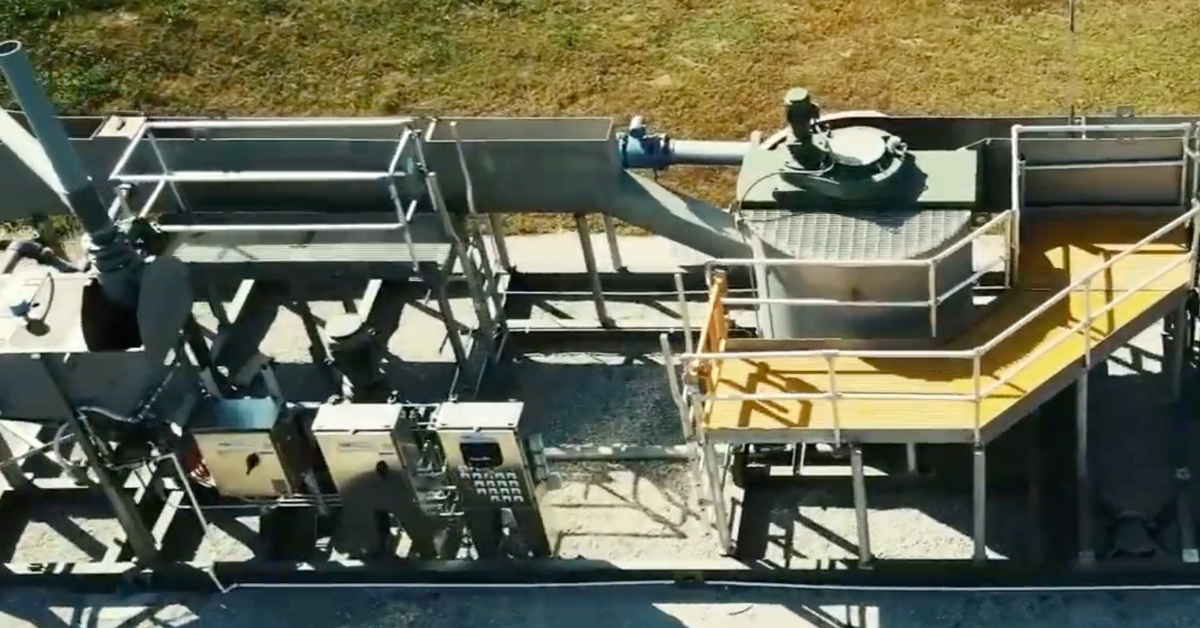

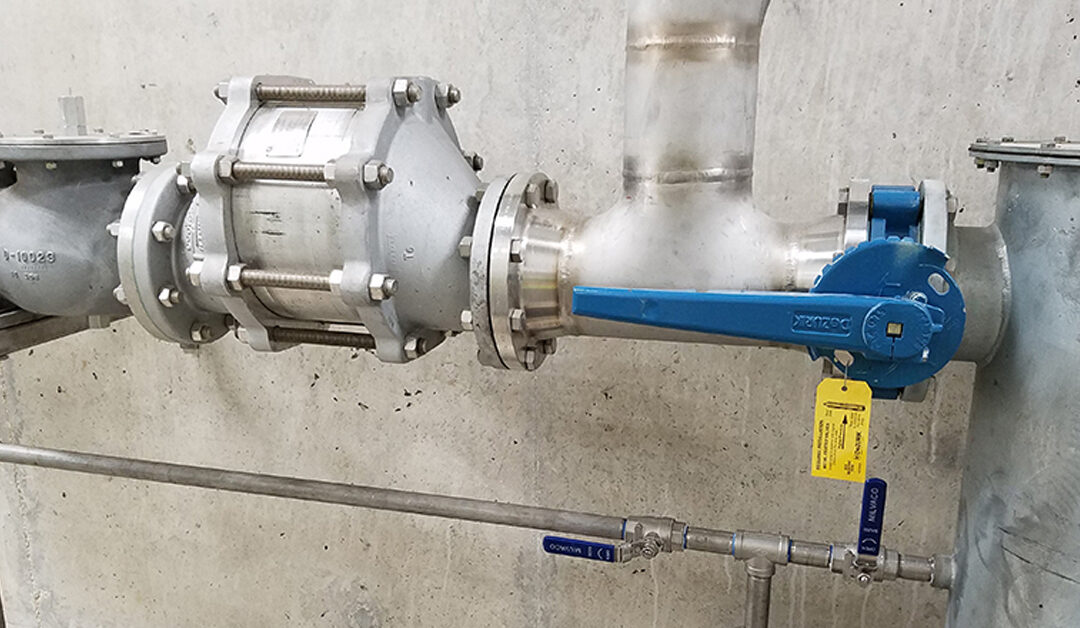

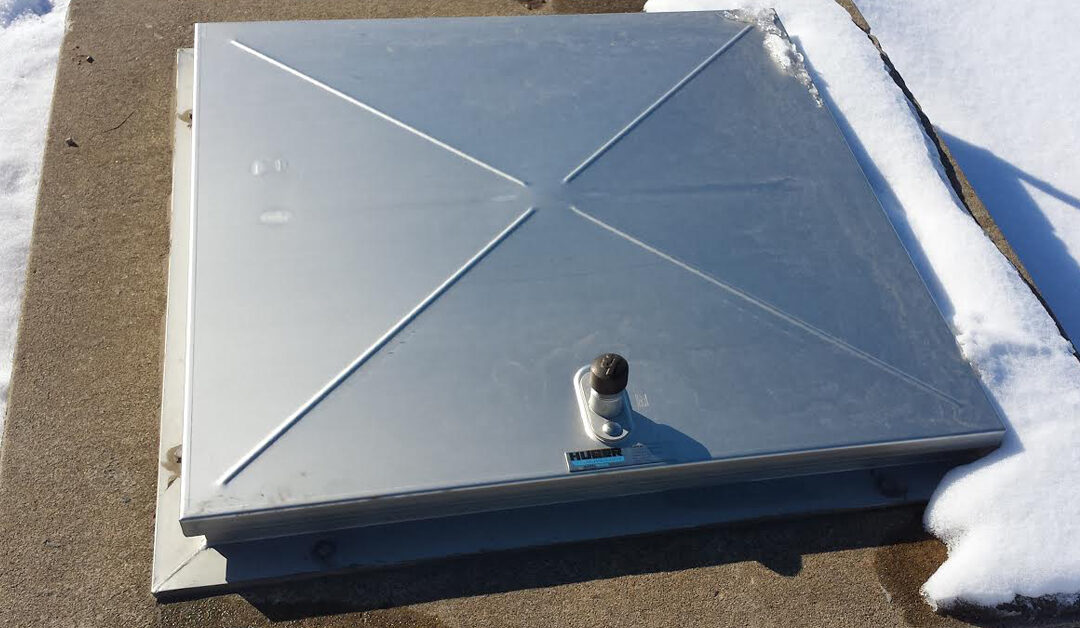

This turnkey project was a good example of a customer coming to us, and we take responsibility for the complete lift station. This helps in keeping costs down, and speed the project along by not involving several different companies and suppliers. In this case, we provided the complete concrete manhole and valve vault, all the ductile iron piping, pumps, guide rails, valves, control panel, level transducer with backup floats, and a cellular dialer for alarm communications.

Who was this turnkey project for?

The project is a new subdivision expansion with a large number of homes, already in the works being constructed as we speak. They’re expecting people to move in soon. The lift station is required to serve the new development and connects to the Eau Claire wastewater collection system. The developer wanted simplicity, and not have to deal with all the rigmarole of involving several different parties and a lot of coordination. We can get it all delivered at a reasonable cost, meeting fast timelines. For some people, such as a developer, that’s quite appealing. We helped the developer through the design process and provided them all of the documentation they needed because they still needed to go through the DNR for approval.

What was the process?

We had to handle the coordination and schedule accordingly due to the weather. We started last fall to ship the concrete lift station wet well and valve vault to enable the contractor to install before the ground froze. They needed the concrete in the ground, so that they could continue with road construction, set their elevation and do all their plat restoration beforehand. Otherwise, they wouldn’t have been able to finish the roadway until this spring and it would have put them behind several months. Working with Energenecs, they were able to expedite some of the project and keep them moving further along.

How was this different from a typical job?

We have supplied over 250 submersible lift stations with integral valve vaults over the years, Our approach is to work closely with a major Wisconsin concrete manufacturer to supply our wet well and valve vault for the site. We also team up with various mechanical and electrical contractors so they see and understand from our submitted drawings exactly what we are providing for their installation. Our lift station expertise often can speed the project along faster than a typical design, bid, build, ship, install style of project involving numerous parties.

What are the benefits of a turnkey system?

It can be faster and less expensive because we do it so often. We’re not reinventing the wheel. We have the knowledge and expertise to select the right equipment and make it work. We provide lift station control panels all the time. It’s easy for us to keep track of everything and keep things moving in a timely and effective manner.

I like working on something that is a complete project that you feel proud you’re handing off something that is a complete package, as opposed to just bits and pieces. In the future if the client requires some maintenance or service, we have the entire project history in our records, and I can go back and help them quickly and effectively.

Lift Stations – arguably – are the most time consuming/problematic portions of sewer projects. Ask any sewer contractor – materials ship in spurts, parts don’t fit, electrical services are incorrectly interfaced, pumps don’t line up with openings, and on and on…..Over the span of my career with Energenecs, I worked on (literally) thousands of lift stations. And, a single source experienced responsible vendor is a God send…..keep it up,…..it’s a highly underrated service to all parties; from the consulting engineer, to the owner, to the contractor.